|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

j. Remove the retaining ring (14) and slide the

tappets in the cylinder block. lf clearance is still

governor ball race (15), catching the fly balls (16)

excessive, the cylinder block is worn and must be

as they are released.

replaced.

g. Inspect the governor cross shaft for wear,

Slide the governor lever (5) and spring (6) from the

scoring, and distortion. Check the fit of the cross

outside end of the governor cross shaft (12).

shaft in the bushing. The shaft-to-bushing

clearance shall be 0.0012 to 0.0027 inch. If

clearance is excessive, replace the cross shaft, the

-

bushing,

or

both.

h. Inspect all other parts for cracks, distortion,

wear, damaged threads, and other damage; replace

damaged parts.

Reassemble the camshaft and governor as shown in

items 13 through 20 of figure 4-7 and in figure 4-

11. Note the following:

from the inside of the crankcase. Install the speed

control bracket (11), regulating disk (10), and

bushing (8) on the outside of the crankcase. Secure

the cross shaft with the retaining ring (7).

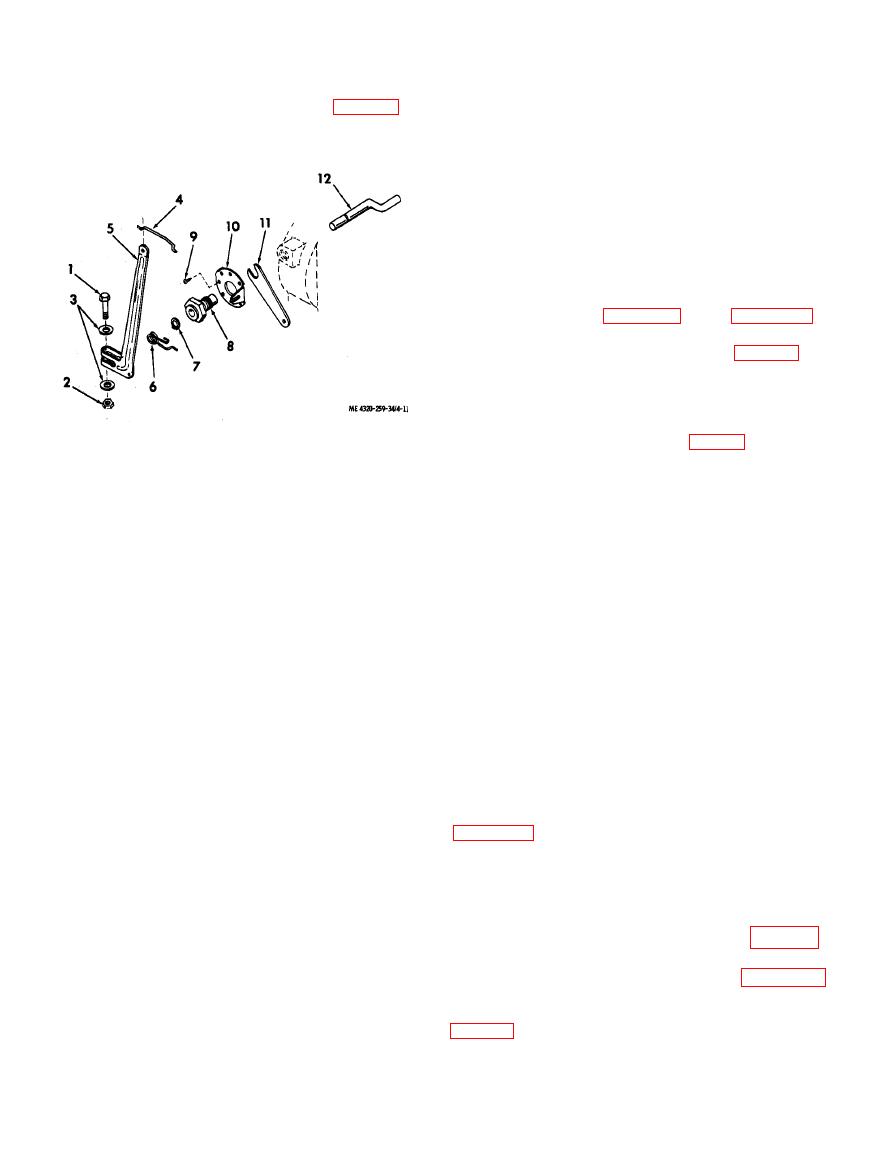

1. Clamping screw

7.

Retaining ring

2.

Nut

Bushing

8.

flyball retainer (18) on the camshaft (19) and

3.

Flat washer

Drive screw

9.

position the governor ball race (15) on the

10.

Regulating disk

4.

Throttle link

cam shaft. Secure the parts with the retaining ring

11.

5.

Governor lever

Speed control bracket

12.

Cross shaft

6.

Torsion spring

(14).

c. Insert the tappets (20) in the cylinder block.

Position the assembled camshaft and governor

assembly in the cylinder block and insert the

l. Remove the retaining ring (7). Unscrew the

cam shaft pin (13) from the bearing plate side of the

governor bushing (8) and remove the bushing,

cylinder block. Tap it into place so that the ends are

regulating disk (10), and speed control bracket

flush with the sides of the cylinder block.

(11). Remove the governor cross shaft (12) from

Caution: Do not attempt to insert the

the inside of the cylinder block.

camshaft pin from the power takeoff side of the

cylinder block. The camshaft pin hole on this

side is smaller in diameter and driving the pin

a. Clean all parts with an approved cleaning

through it may damage the cylinder block.

solvent; dry thoroughly.

d. Check the camshaft end play with a feeler

b. Inspect the camshaft for chipped or broken

gage inserted between the camshaft and block. End

gear teeth, scored or worn cams, and worn or scored

play shall be 0.005 to 0.020 inch. If end play is

bore. Insert the camshaft pin into the camshaft and

excessive, add shim washers at the breaker cam end

check the clearance. Camshaft pin-to-camshaft

of the camshaft.

c l e a r a n c e shall be 0.0010 to 0.0025 inch. If

e. Install the crankshaft and main bearings

clearance is excessive, replace the camshaft. If the

(para 4-14). Make sure timing marks on the

camshaft pin is ridged, grooved, or worn, also

crankshaft and camshaft are properly alined. After

replace the camshaft pin.

installing the crankshaft, check that the crankshaft

c. Inspect the governor ball race for scoring or

and camshaft rotate freely without binding.

distortion; replace a damaged race.

f. Install the magneto and flywheel (TM 5-4320-

d. Check the governor flyballs for wear, scoring,

259-12).

out-of-round condition, pits, and other damage;

replace damaged fly balls.

10).

e. Inspect the flyball retainer for cracks,

distortion, and wear; replace if damaged.

6).

f. Inspect the valve tappets for wear and scoring.

i. Install the centrifugal pump on the engine

Check the fit of the valve tappets in the bores of the

cylinder block. Valve tappet clearance in the

cylinder block shall be 0.0005 to 0.0020. If

clearance is excessive, check the fit of new valve

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |