|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ance still is not obtained, refer to paragraph 6-19c(6).

(8) As an alternate method of checking crank

pin bearing journal-to-connecting rod bearing clearance,

install a piece of 0.003 inch thick feeler stock between

(4) If new pistons and pins are being used

the bearing and journal. Lubricate the bearing journal

they may be installed as received, as they have been

with SAE 10 engine oil. Install the connecting rod cap.

pre-pin fitted.

Tighten the connecting rod capscrews to 57-59 ft-lbs of

(5) If the pistons and pins are not being

torque. Try to slide the connecting rod alternately

replaced check the clearance between the piston pins

toward the front and rear of the engine. If clearance is

and the sleeve bearings. If a piston pin will drop through

within tolerance, a definite drag will be felt. If clearance

a piston under its own weight, it is considered to have

is not within tolerance, replace the connecting rod

too much clearance. If the clearance is found too loose

bearings and recheck the clearance.

provide the proper fit. Which is a push fit with piston

e. Reassembly.

and pin both at room temperature.

(6) Refer to figure 6-21 and check piston ring

(1) Refer to figure 619 and reassemble

gap by sliding the piston rings squarely into the cylinder

connecting rod and piston sets, using standard piston

sleeves in which they will be used. Check the ring gap

ring expander.

with feeler stock. If the gap is too small, file the rings to

provide a proper gap.

(2) Refer to figure 6-21 ar4 check piston ring

side clearance with feeler stick.

(7) Check the crankpin bearing journal to

connecting rod bearing clearance with plastigage as

f. Installation.

follows: Place a piece of plastigage near the oil hole of

the bearing cap. Position the cap on the connecting rod

and secure with the two capscrews.

Tighten the

(1) Refer to figure 6-22 and install connecting

capscrews to 57-69 ft-lbs torque. Remove the bearing

rod and piston sets in cylinder block, using standard ring

and bearing cap. Check the bearing journal-to bearing

clearance using plastigage if clearance is not between

(2) Install rod bearings in connecting rods and

0.0005 and 0.003 inch, replace the connecting rod

rod caps.

bearings and recheck the clearance.

(3) Tighten connecting rod capscrews to 57-

59 ft-lbs of torque.

(4) Refer to paragraph 6-15c and perform

operations described.

6-17. Flywheel and Flywheel Housing

a. General. The flywheel and flywheel housing are

located at the end opposite the cooling fan, in the

engine assembly. The flywheel serves as a means of

maintaining engine momentum and aids in the starting

of the engine. The flywheel housing surrounds the

flywheel and serves as a means of attaching equipment.

b. Removal.

(1) Refer to figure 5-1 and remove engine

assembly and housing.

(2) Refer to figure 6-23 and remove flywheel.

(3) Refer to figure 6-24 and remove cap

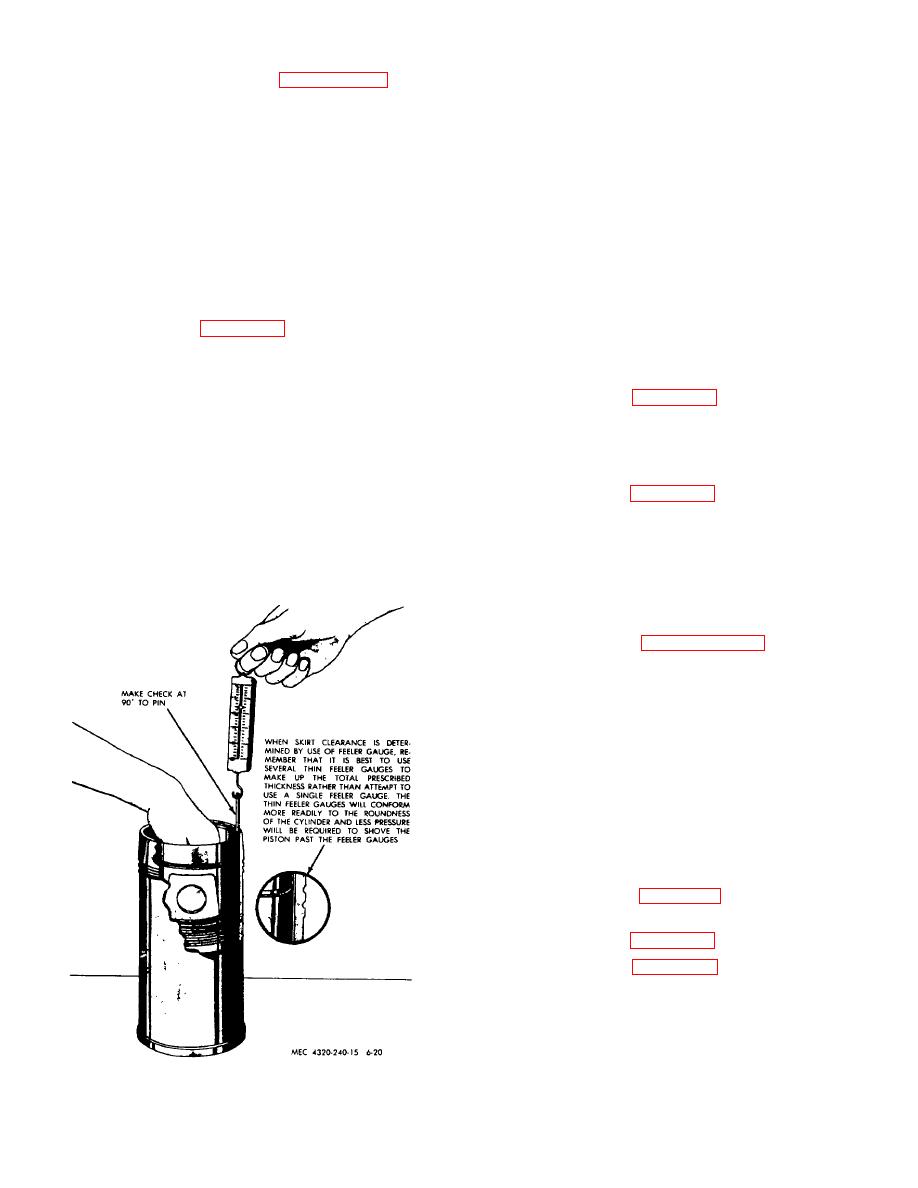

Figure 6-20. Fitting Piston

6-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |