|

|||

|

|

|||

|

Page Title:

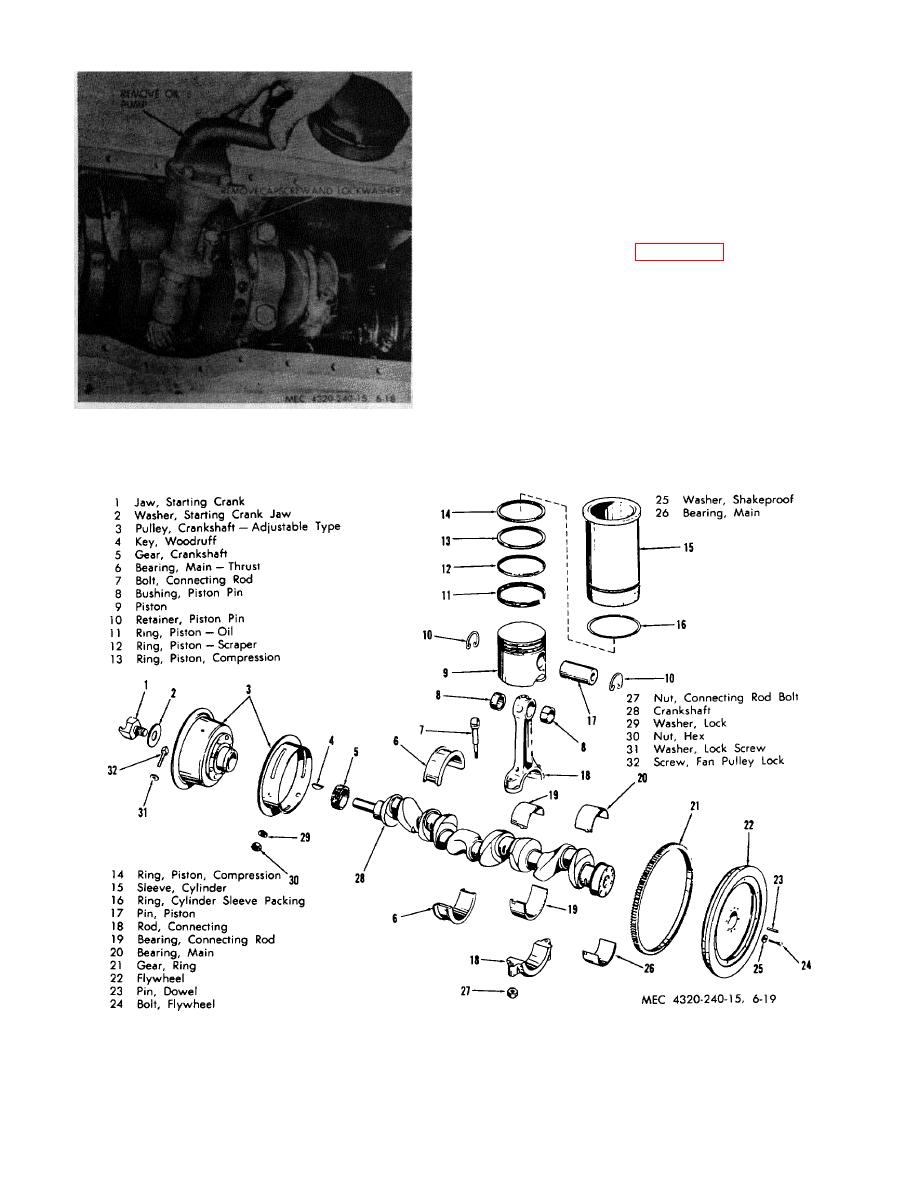

Figure 6-19. Crankshaft, pistons, connecting rods, bearings |

|

||

| ||||||||||

|

|

d. Cleaning, Inspection, and Repair.

(1) Clean all parts in an approved cleaning

solvent; dry with clean dry, compressed air.

connecting rods for cracks, distortion, scoring, pitting or

other defects. Replace piston rings and damaged or

defective parts.

(3) Refer to figure 6-20 and check piston fit

using a piece of 0.015 inch feeler stock cut 1/2 inch

wide. Dress the edge of the feeler stock with a stone to

remove burs and feathered edges. The block and

pistons must be at room temperature when piston fit is

tested. Position the feeler stock midway between the

piston pin bosses. With the piston and feeler stock

inserted about 2 inches into the sleeve the feeler stock

must pull from the block with 5 to 10 pounds pull. If the

feeler stock does not offer enough resistance, perform

same test with a new standard size piston. If sufficient

resist

Figure 6-18. Oil pump removal and installation.

Figure 6-19. Crankshaft, pistons, connecting rods, bearings.

6-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |