|

|||

|

|

|||

|

Page Title:

Crankshaft, Crankshaft Bearings, and Camshaft |

|

||

| ||||||||||

|

|

and recheck eccentricity. If eccentricity

still exceeds 0.008 inch, replace the

flywheel.

(6) Refer to figure 6-25 and check runout of

the flywheel housing face by mounting a

dial indicator on the flywheel with the

indicator tip against the inside of the face

of the flywheel housing.

Rotate the

crankshaft through one revolution. Hold

pressure against the flywheel to eliminate

end play. If runout exceeds 0.008 inch,

clean the mounting surfaces of the

flywheel housing and the block. Recheck

flywheel housing runout. If the runout is

still not within limits, replace the flywheel

housing.

(7) Refer to figure 625 and check eccenricity

t

of the flywheel housing bore by mounting

a dial indicator on the flywheel with the

indicator tip against the inside of the

flange of the flywheel housing. Rotate the

engine through one revolution. If housing

bore eccentricity exceeds 0.008 inch

loosen the flywheel housing mounting

bolts and tap the housing into its proper

position with a soft hammer.

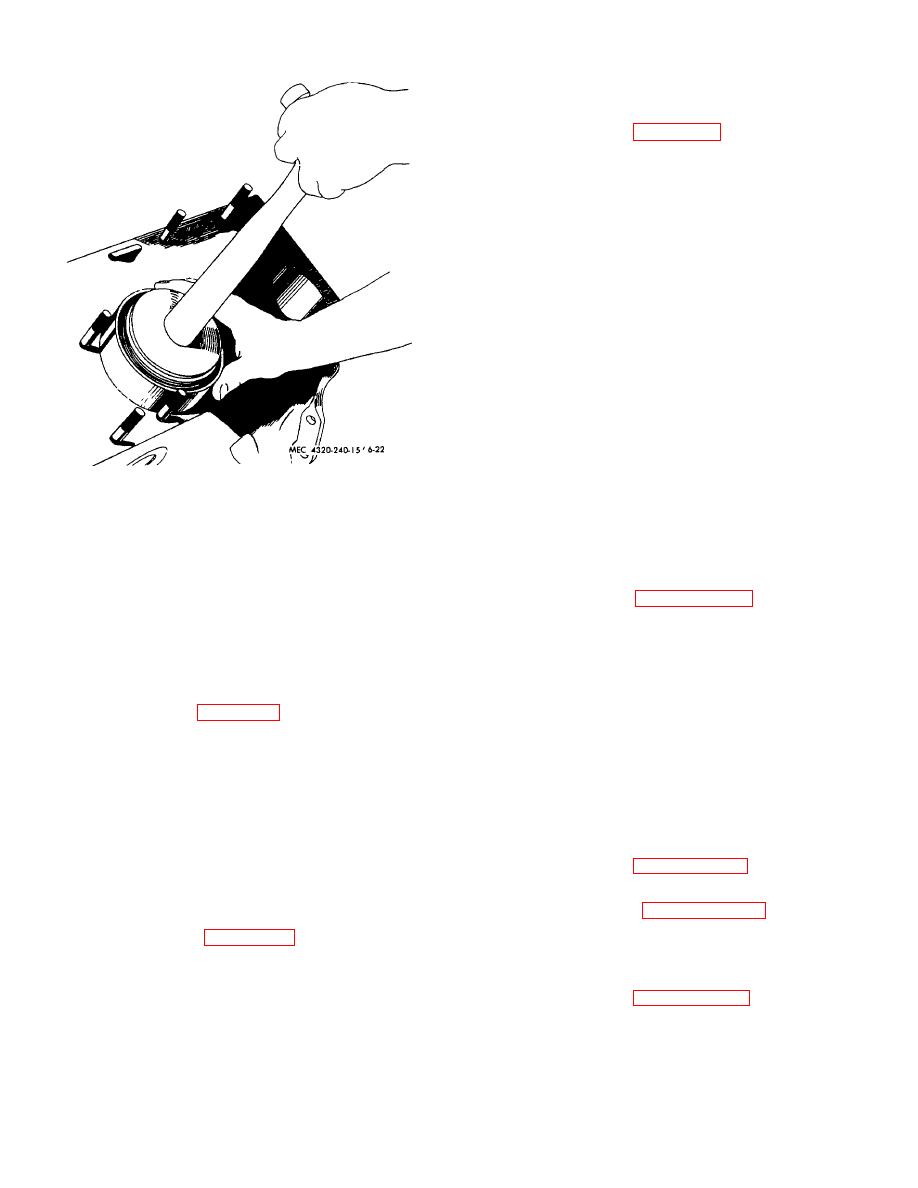

Figure 6-22. Piston installation using standard ring

Tighten the bolts and recheck housing

bore eccentricity. If the housing cannot

be brought into true position, replace the

remove the ring gear from the flywheel. When cutting

housing.

the ring gear, be extremely careful not to damage the

(8) Refer to paragraph 5-22b and install the

flywheel. Heat the replacement ring gear in an oven

engine assembly.

and cool the flywheel in a refrigerator. Position the

replacement ring gear on the flywheel. As the ring gear

6-18.

Crankshaft,

Crankshaft

and

and the flywheel approach the same temperature, the

Camshaft

ring gear will contract to a very tight fit of the flywheel.

a. General. The crankshaft is located at the lower

(3) Refer to figure 6-23 and install flywheel.

end of engine assembly. Its purpose is to change the

(4) Refer to figure 625 and check flywheel

reciprocating action of the pistons into revolutions of the

runout by mounting a dial indicator on the

flywheel. The camshaft is driven by the crankshaft

flywheel housing with the indicating tip

through a gear train. It is designed to maintain the

against the face of the flywheel. Rotate

timing of the entire engine.

the crankshaft through one full revolution.

Hold pressure against the flywheel to

b. Removal.

eliminate crankshaft end play. If flywheel

runout exceeds 0.008 inch, remove the

(1) Refer to paragraph 5-22a and remove the

flywheel and clean the crankshaft flange

engine and housing assembly.

and flywheel seat. Install the flywheel and

recheck runout. If runout still exceeds

(2) Refer to paragraph 5-23a and remove

0.008 inch, replace the flywheel.

housing from engine.

(5) Refer to figure 6-25 and check flywheel

(3) Position engine on side, be careful not

eccentricity by mounting a dial indicator

damage any of the protective housing.

on the flywheel housing, position the tip

against the inside of the counterbore of

(4) Refer to paragraph 3-46d and remove the

the flywheel.

Rotate the crankshaft

magneto.

through one revolution.

If flywheel

eccentricity exceeds 0.008 inch, loosen

(5) Refer to paragraph 331b and remove the

and retighten the flywheel mounting bolts

fuel pump.

6-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |