|

|||

|

|

|||

|

Page Title:

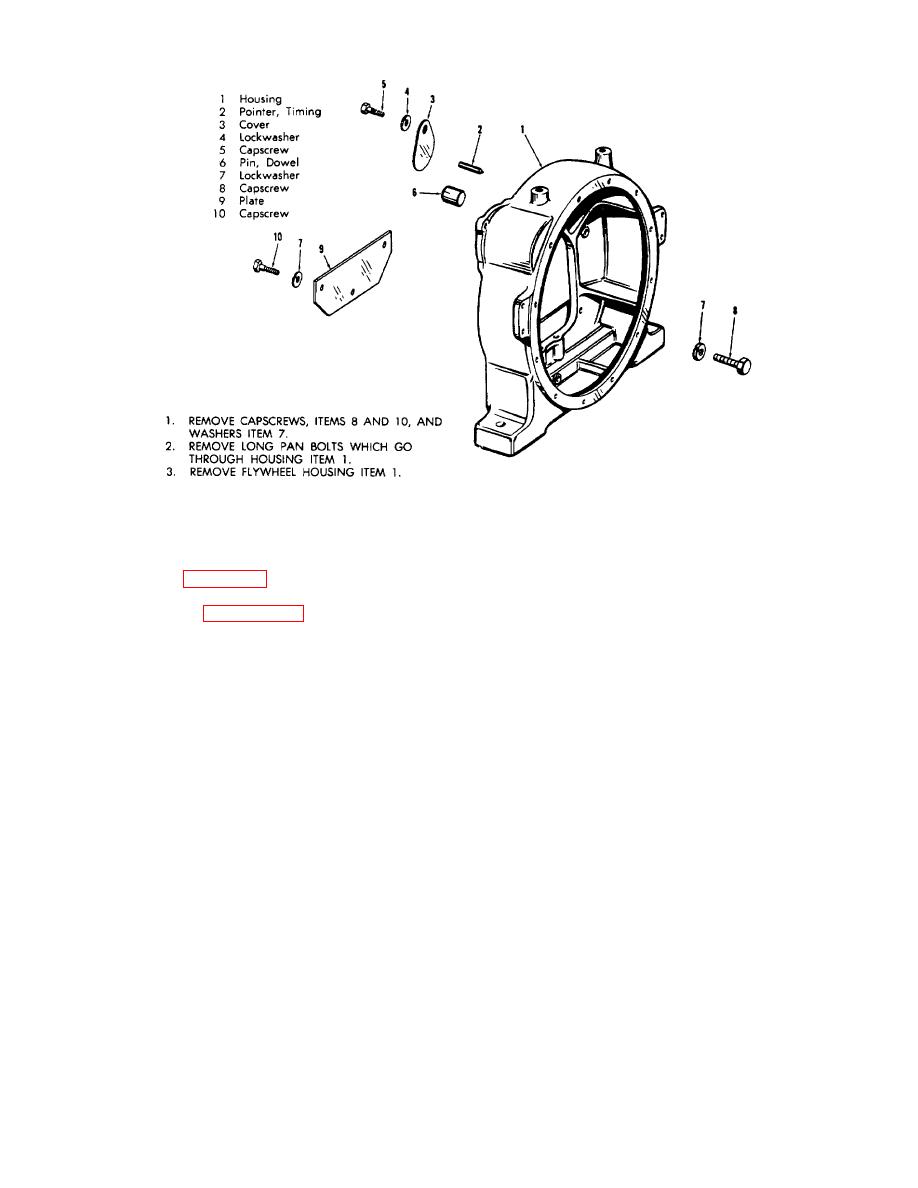

Figure 6-24. Flywheel housing removal and installation. |

|

||

| ||||||||||

|

|

MEC 4320-240-15/6-24

Figure 6-24. Flywheel housing removal and installation.

(14) Refer to figure 6-29 and remove rear seal.

c. Cleaning and Inspection.

(15)

Refer to figure 6-30 and remove the

(1) Clean all metal parts in an approved cleaning

camshaft.

solvent. Dry with clean, dry, compressed air. Make

sure that the crankshaft oil parts are open by blowing

compressed air through each port.

Note: Unless the engine is inverted on a work stand or

tipped on its side on a table, provision must be made

to keep the cam followers lifted clear of the cam lobes

(2) Inspect the crankshaft for cracks, scored or

while the cam is withdrawn. This may be done with

grooved bearing journals, damaged key slots and bolt

small wire loops, wooden wedges, tape around the

holes, or other defects.

upper portion of the follower, or any other method that

works out conveniently. Withdraw the camshaft from

its bushings or case.

(3) Inspect the camshaft for cracks, pitting, worn

or scored lobes or bearing journals, damaged threads

Caution: If the edges of the cam lobes are

and key slots, or other defects.

allowed to drag across the bushings,

grooves and scratches may be formed that

d. Installation.

will impair lubrication and service life.

(1)

If the crankshaft gear is damaged or

(16) Remove capscrews, rod caps, and rod

defective, refer to figure 6-31 and remove the gear from

bearing from connecting rods.

the crankshaft.

(17) Remove capscrews, washers, main bearing

(2) Position the upper half of the main bearings in

caps, and main bearings.

the block. Install the crankshaft in the block. Install the

lower half of the main bearings in the bearing caps.

(18) Remove the crankshaft from cylinder blocks.

6-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |