|

|||

|

|

|||

|

Page Title:

Section IV. PISTON AND CONNECTING ROD |

|

||

| ||||||||||

|

|

TM 5-4320-237-15

Section IV. PISTON AND CONNECTING ROD

95. General

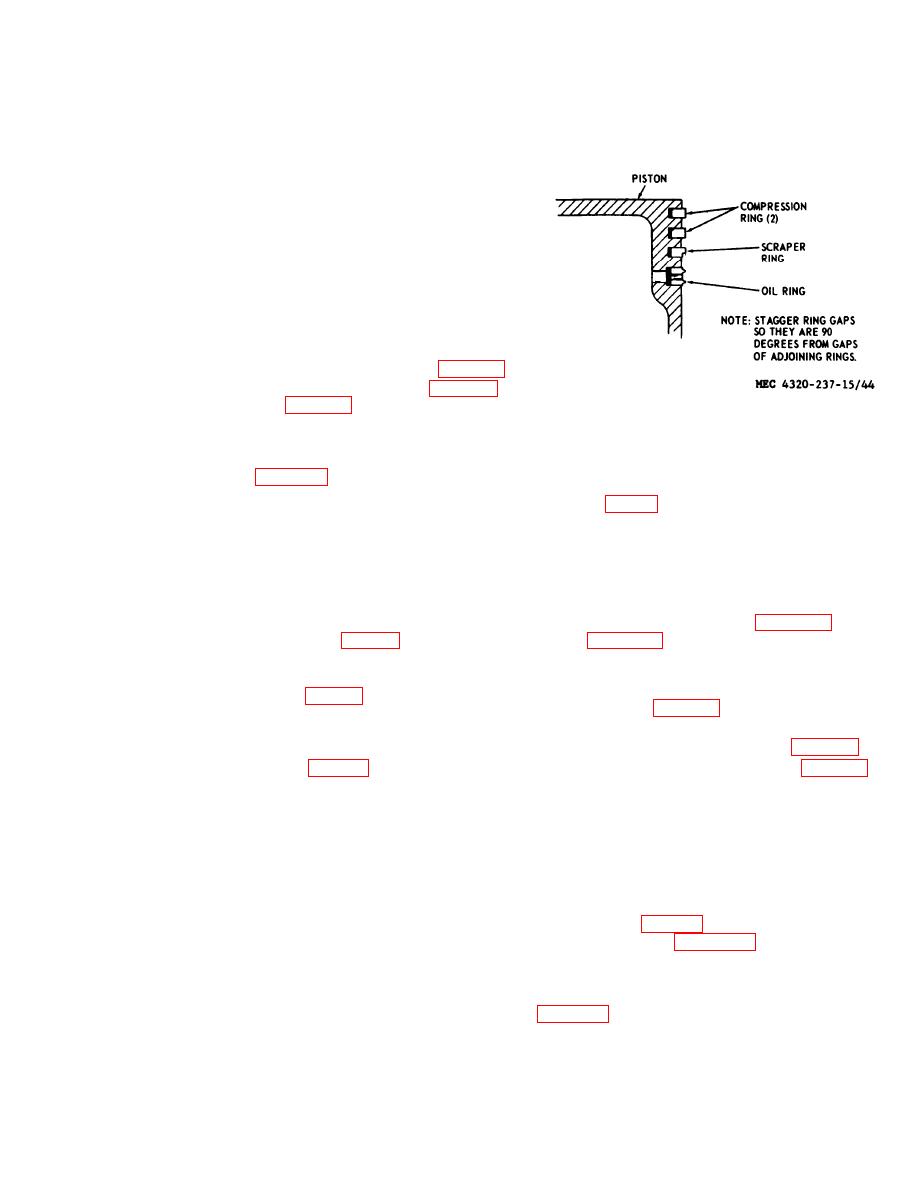

The engine uses a conventional piston and

connecting rod assembly. The crankpin bear-

ing and wrist pin bearing are an integral part

of the connecting rod and are not removed

from the rod at disassembly. The piston uses

four piston rings, two compression rings, one

scraper ring, and one oil ring.

a. Removal.

(1) Remove the cylinder head (para 65).

(2) Remove the engine base (para 95).

(3) Refer to figure 42 to remove the as-

sembled piston and connecting rod.

b. Disassembly. Disassemble the piston and

connecting rod in the numerical sequence as

(5) Check the fit of the wrist pin in the

indicated in figure 43.

piston and connecting rod. Refer to

c. Cleaning and Inspection.

(1) Clean all parts with an approved clean-

(6) Inspect all other parts for cracks, dis-

ing solvent; dry thoroughly. Use the

tortion, and other damage; replace

sharpened end of a broken piston

damaged parts.

ring to scrape carbon deposits from

d. Reassembly. Reassemble the piston and

piston ring grooves.

(2) Inspect the piston for cracks, distor-

connecting rod in the reverse of the numeri-

tion, scoring, wear, and other dam-

cal sequence as illustrated in figure 43. Re-

fer to figure 44 for location of various piston

age. Refer to table 1 for tolerances.

rings.

(3) Inspect the connecting rod for cracks,

distortion, wear and other damage.

e. Installation.

Refer to table 1 for tolerances.

(1) Refer to figure 42 and install the as-

(4) Inspect piston rings for cracks, dis-

sembled connecting rod and piston.

tortion, and other damage. Check

(2) Install the engine base (para 94).

piston ring gap and side clearance.

Refer to table 1 for tolerances.

(3) Install the cylinder head (para 65).

Section V. CRANKSHAFT

97. General

98. Crankshaft

The crankshaft rides in tapered roller bear-

a. Removal.

ings in the crankcase. Bearing end play is

(1) Remove the piston and connecting

taken up by shims installed under the driven

rod (para 96).

end bearing plate. Cork seals prevent the oil

(2) Refer to figure 45 and remove the

from leaking around the rotating crankshaft.

crankshaft assembly.

Both ends of the crankshaft are threaded--

b. Disassembly. Disassemble the crankshaft

one end to receive the impeller of the pump

in the numerical sequence as illustrated in

and the other end to mount the starting rope

pulley.

c. Cleaning and Inspection.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |