|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-237-15

and reaessembly.

Inspect all other parts for cracks,

installation.

(4)

wear, distortion, and other damage;

replace all damaged parts.

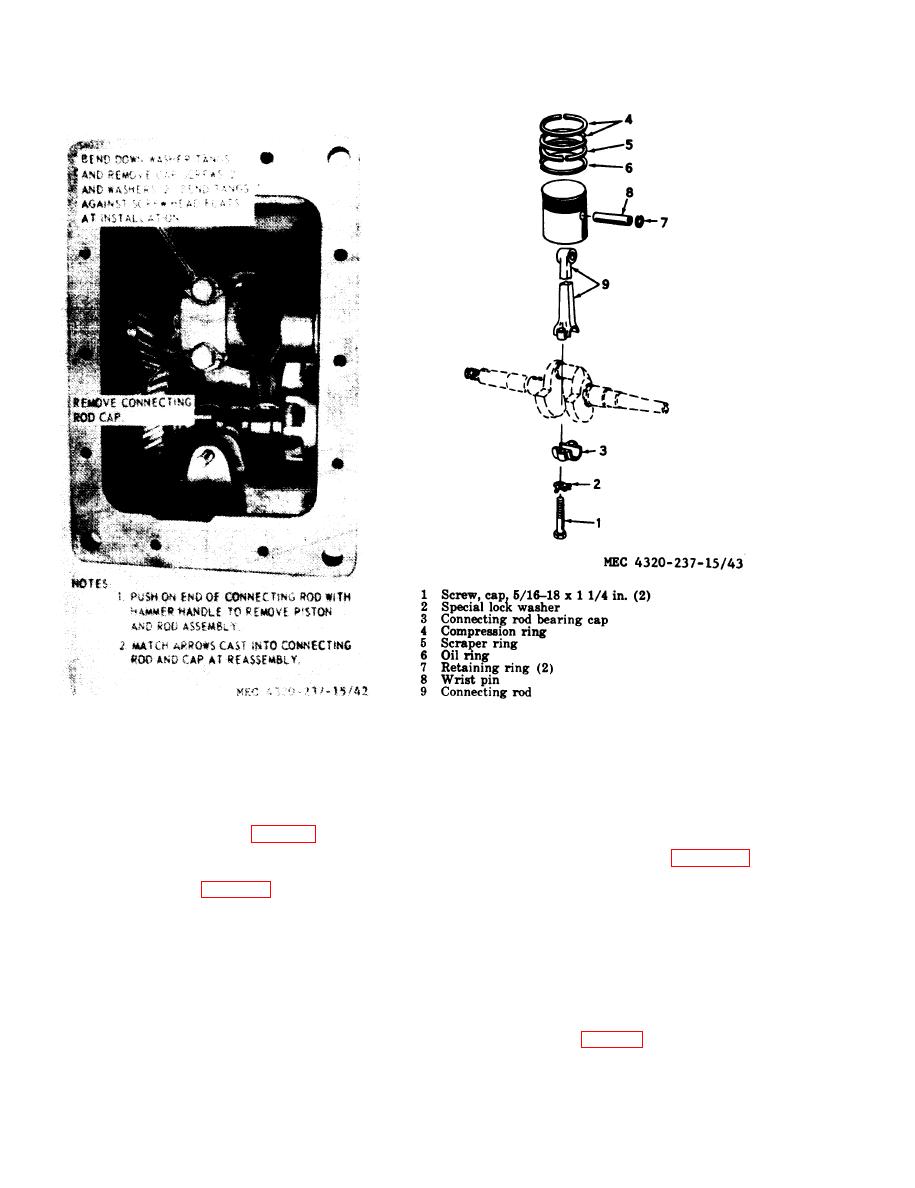

c. Reassembly and Installation.

a. Removal and Disassembly.

(1) Reassemble the oil pump into the

(1) Remove the engine (para 73).

base in the reverse of the numerical

(2) Remove the engine base and oil

sequence as illustrated in figure 41.

pump in the numerical sequence as

After assembly, fill the base sump

illustrated in figure 41.

with oil and pump the plunger up

b. Cleaning and inspection.

and down with a screwdriver to as-

(1) Clean all parts with an approved

sure that the pump draws oil into

cleaning solvent; dry thoroughly.

the oil pump body to maintain a

(2) Inspect the oil pump check balls for

full oil pump body.

(2) When pump operation has been

dents, scoring, out-of-roundness, and

other damage.

checked, install the engine base on

(3) Inspect the plunger for scoring,

the engine.

wear, or distortion.

(3) Install engine (para 73).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |