|

|||

|

|

|||

|

Page Title:

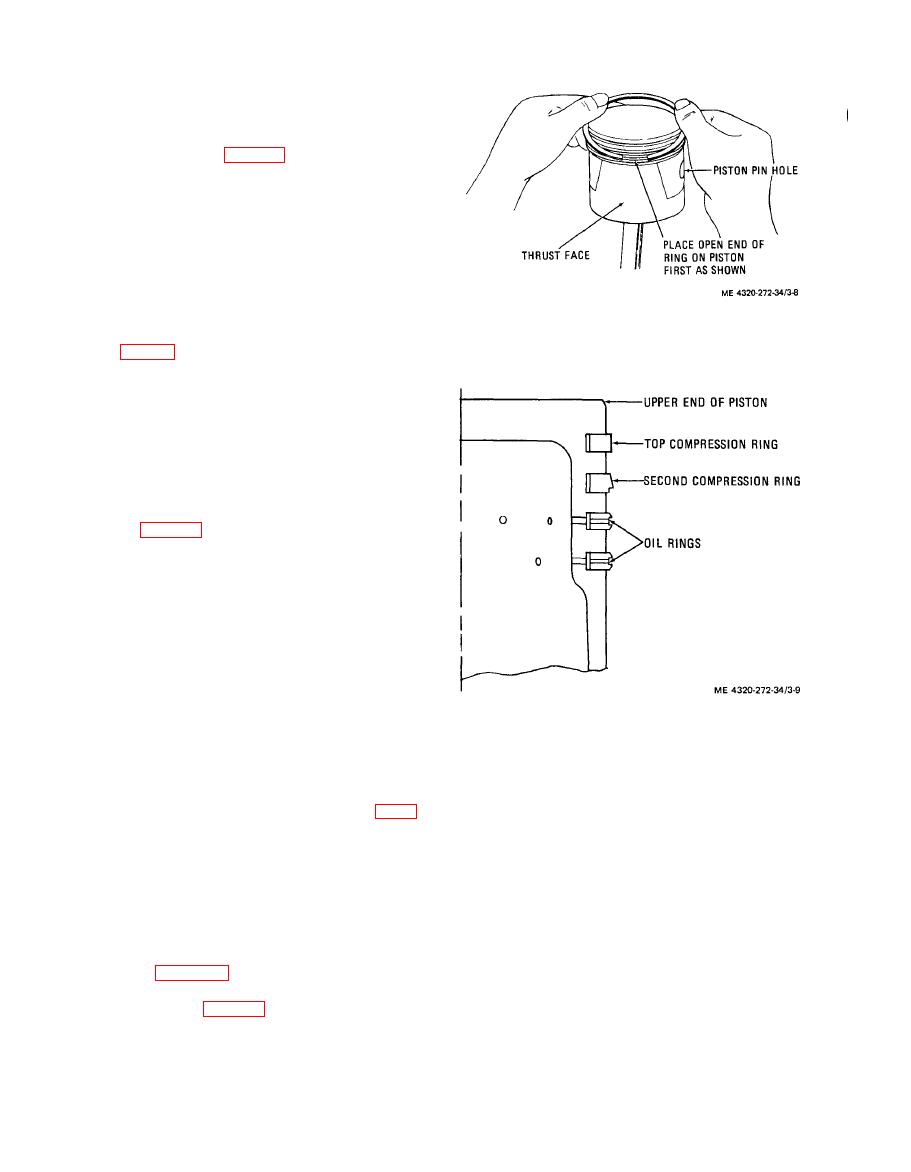

Figure 3-9. Piston ring placement. |

|

||

| ||||||||||

|

|

(7) Inspect all other parts for cracks, distor-

tion, damaged threads, wear, and other damage;

replace damaged parts.

c. Reassembly and Installation.

(1) Use a feeler gage to check the piston fit in

the cylinder bore. Refer to table 3-1 for proper clear-

ance. The block and pistons must be at room tempera-

ture when piston fit is checked. You must measure the

clearance between the piston and cylinder at the center

of the piston skirt thrust faces. The thrust faces are 90

from the axis of the piston in hole. Check the fit of the

piston when it is approximately 2 inches down in the

cylinder bore in an inverted position. If the clearance

is too great, check the fit of a new standard size piston

in the cylinder bore.

(2) Check the clearance between the piston

pins (17, fig. 3-11) and sleeve bearings (19). Clearance

must be between 0.0002 an 0.0007 inch. If clearance is

not within this tolerance, press new sleeve bearings

into the connecting rods and ream and hone to provide

the proper clearance. After honing, 75 percent of the

sleeve bearing surface must contact the piston pin.

(3) If new pistons and piston pins are being

used, press a new sleeve bearing (19) into each con-

necting rod (15). Ream and hone the sleeve bearing to

provide proper clearance between bearing and piston

pin; refer to table 3-1.

(4) When pins, bushings, and pistons of the

proper size have been matched, assemble the pistons

to the connecting rods. The specified pin clearance

should permit a hand push fit in the piston at room

temperatures. Position a connecting rod in its piston.

Install the piston pin; secure with the new piston pin

retaining ring (16).

(5) To check the piston ring gap, slide the pis-

ton rings squarely into the cylinders in which they will

be used. You can insure squareness by pushing the

piston rings in th cylinder bore with an inverted pis-

ton. Remove the piston and check the ring gap with

feeler gage. If the ring gap is not at least 0.025 inch,

carefully file the rings to provide a larger gap.

(7) Assemble the remaining pistons, piston

(6) Install the bottom oil ring first by placing

pins, connecting rods, and piston rings.

the open end of the ring on piston, as shown in figure

(8) Lubricate the pistons, rings, rod bearings,

3-8. Spread ring only wide enough to slip over piston

and cylinder walls with engine oil before installing the

and into correct ring groove. You must take care not to

pistons. Stagger the piston ring gaps approximately

distort the ring. Install the remaining rings in the same

90 apart around the piston.

manner, working up from the bottom and installing

(9) Use a suitable ring compressor to compress

the top compression ring last. When you install the

the piston rings and install the assembled pistons and

compression ring that is second from the top, be sure

connecting rods in the same cylinders from which they

you install it on the piston with the scraper edge down,

were originally removed. The arrow on the top of the

piston must point in the direction of crankshaft rota-

otherwise oil pumping and excessive oil consumption

will result. See figure 3-9. Rings must be free to move

tion. Wrap the bottom end of the connecting rods with

in the groove. Check side clearance of each ring after

a cloth so that you do not damage the cylinder walls

you install it; refer to table 3-1 for clearances.

during installation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |