|

|||

|

|

|||

|

Page Title:

Section II. ENGINE OVERHAUL AND REPAIR |

|

||

| ||||||||||

|

|

Normal clearances

Maximum allowable

(in inches)

Component points of

clearance

Minimum

Maximum

measurement

0.0062

0.0052

0.0112

Piston to cylinder (at piston skirt thrust faces)

Piston ring gap

0.0020

0.0040

Top ring

0.0015

0.0035

2nd ring

0.0010

0.0030

3rd and 4th groove oil rings

0.0080

0.0150

Connecting rod to crankpin side clearance

0.0015

0.0030

Connecting rod shell bearing to crankpin bearing journal

0.0003

0.0000

Piston pin to piston

0.0007

0.0002

Piston pin to connecting rod sleeve bearings

0.0025

0.0080

0.0045

Valve stems to guides

0.0020

0.0050

Crankshaft end play

0.0040

0.0030

Idler gear to shaft shoulder

Section II. ENGINE OVERHAUL AND REPAIR

NOTE

Major repair or overhaul requires that

the engine be mounted on an engine

overhaul stand. You will find it conve-

nient to remove all engine accessories

first. Refer to TM 5-4320-272-12.

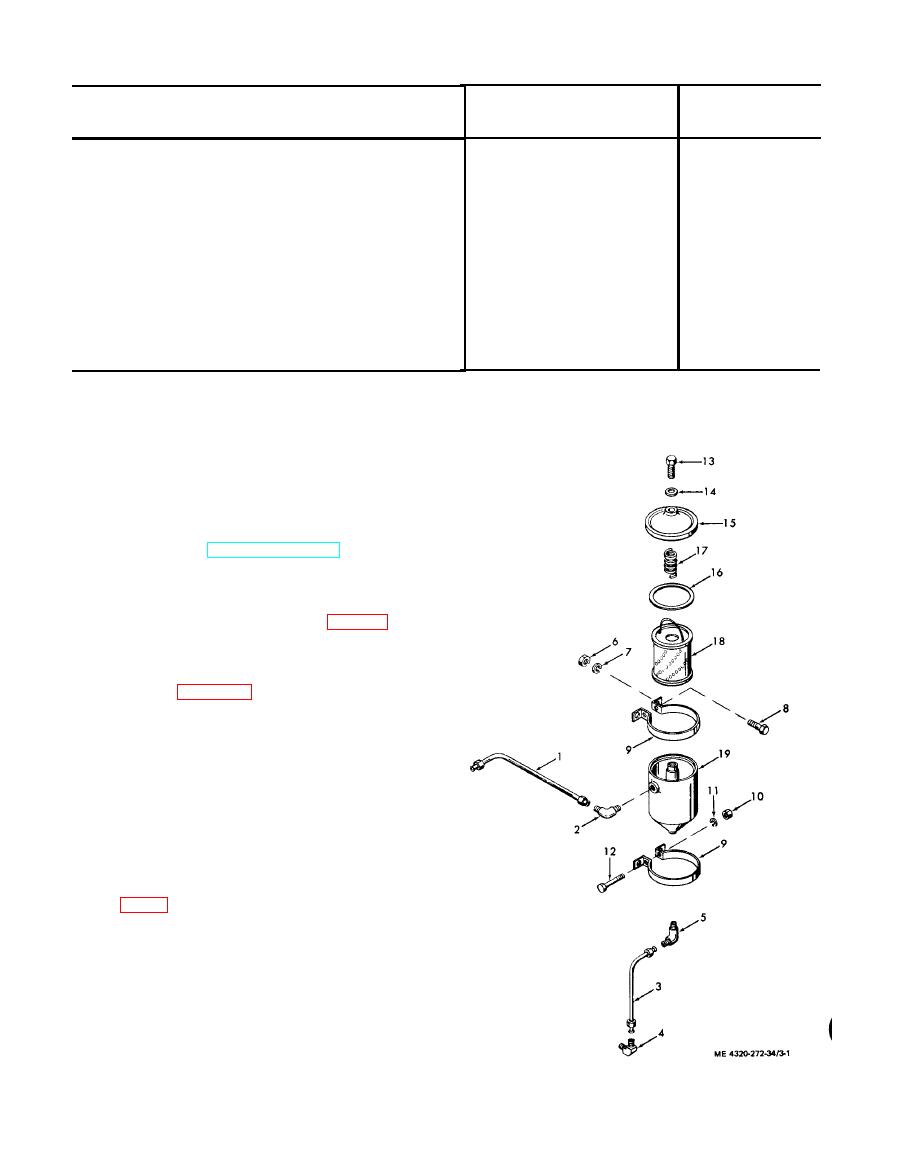

3-4. Oil Filter

a. Removal and Disassembly.

(1) Remove the drain plug (1, fig. 3-13) and

drain the engine oil into a suitable container.

(2) Disconnect the oil tube from the governor.

(3) Remove and disassemble the oil filter and

lines as shown in figure 3-1.

KEY to fig. 3-1:

11. Lock washer

1. Tube

12. Screw

2. Elbow

13. Cover screw

3. Tube

14. Screw gasket

4. Elbow

15. Cover

5. Elbow

16. Cover gasket

6. Nut

7. Lock washer

17. Spring

18. Filter element

8. Screw

19. Oil filter body

9. Oil filter clamp

10. Nut

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |