|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

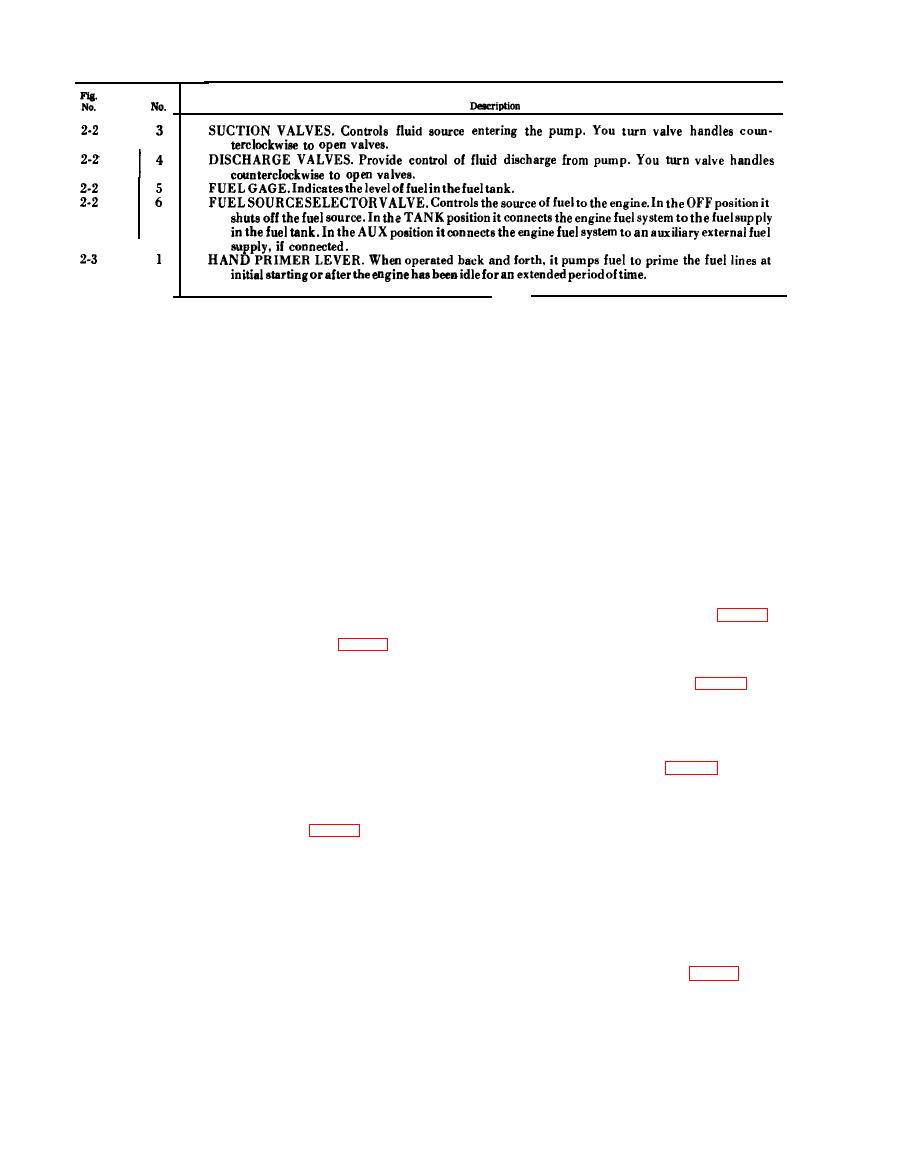

Table 2-1. Controls and Instruments-Continued

+

revolutions of the crankshaft. If it does not, do not

2-3. Starting

continue to crank with the starter. You should use

Start the pumping assembly as follows:

starting cycles. Excessive

short, intermittent

CAUTION

cranking will cause the starting motor to overheat

Make sure you prime the pump before

and may damage it. However, more cranking is

attempting to start it. Starting a dry

normally necessary in cold weather than in warm.

p u m p m a y damage t h e s h a f t s e a l

i. After the engine starts, push in the choke

making seal replacement necessary.

control as necessary to provide smooth engine

a. Close the suction valves. Check that the drain

operation. When the engine is warmed up, you

valve at the bottom of the pump housing is closed.

must push in the choke all the way.

Remove the priming fill cap (fig. 1-2) and fill the

j. Run the engine at high idle speed for a few

pump housing to the level of the plug with the fluid

minutes to allow it to warm up before applying the

to be pumped.

pump load.

b. Open the air eliminator vent valve (1, fig. 2-

2).

2-4. Operation

c. If the engine is being started for the first time,

After starting, operate the pumping assembly as

or if the unit has been standing idle for a con-

follows:

siderable length of time, you will need to prime the

fuel system, filling the fuel lines and the carburetor

to provide fluid from the required source.

float bowl. Use the hand primer lever (1, fig. 2-3).

b. Open the discharge valve (4) to direct the

When priming, a distinct resistance to movement of

fluid to the required destination.

the hand primer must be felt. If you do not feel this

resistance,

turn the engine crankshaft one

increase engine speed so that the tachometer in-

revolution so that the fuel pump lobe on the

dicates approximately 1000 rpm. Pump should

camshaft is rotated out of engagement with the fuel

pick up prime within a few minutes. Fluid flow

pump cam follower to permit movement of the fuel

from the pump is indicated by movement of the

pump diaphragm with. the lever. Hand prime for

check valve override handle (2, fig. 2-2) as the

about 20 or 30 strokes. You will feel less resistance

check valve is pushed from its seat.

to hand primer lever movement when the fuel bowl

d. If prime is not made within a few minutes,

is filled.

you can increase engine speed to 1500 rpm until

prime is achieved, then reduce speed immediately

way.

t o 1000 rpm. This will reduce shock in the

e. Pull out the choke control (11) all the way.

discharge lines as they fill up with fluid.

f. Pull out on the oil pressure safety switch

e. Watch the pump discharge pressure gage and

plunger (4) and engage the spring clip into the

regulate the discharge valve(s) to maintain the

recessed underside of the housing to hold the switch

required flow.

contacts open for starting. You must reset this

f. Increase engine speed as required. During

switch each time you start the pump.

operation, maintain an indication of at least 5

g. Press and hold the starter switch (6). The

inches on the engine vacuum gage (9, fig. 2-1). An

starting motor should crank the engine. After

indication of less than 5 inches means that the

several revolutions of the crankshaft, push in the

pump engine is overloaded. You can control the

choke control (11) half way.

pump load by regulating the discharge valves.

h. The engine should start after a few

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |