|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

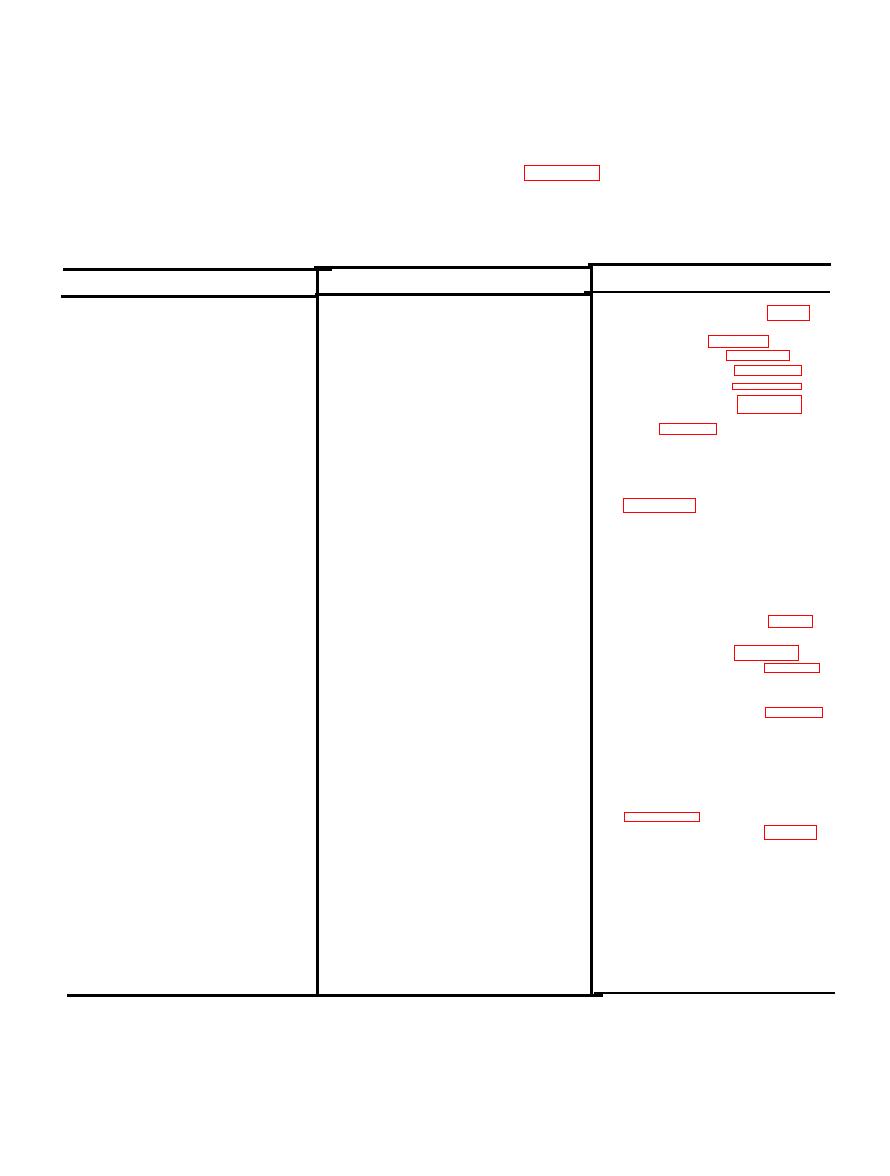

Section V. TROUBLESHOOTING

this chart do not correct the malfunction, report the

4-7. General

trouble to direct support maintenance.

This section describes troubles which might occur

Trou-

Maintenance

during operation of the pumping assembly, along

4-8. Organizational

with probable causes and corrective actions relating

bleshooting Chart

to the troubles. Only those malfunctions which are

Refer to table 4-2 for troubleshooting which is

within the scope of organizational maintenance are

allocated to the organizational level of main-

included in this chart. If corrective actions given in

tenance.

Chart

Corrective Action

Malfunction

Probable Cause

a. Fuel line clogged.

1. Engine fails to start.

19).

b. Faulty magneto timing.

c. Magneto defective.

d. Defective capacitor

e. Carburetor out of adjustment.

f. Carburetor defective

g. Clean, regap, or replace spark

g. Spark plug fouled or defective.

plug (para 4-15).

h. Check spark plugs, cables and

h. Faulty ignition system.

magneto outputs per section

VIII.

a. Service fuel strainer; replace filter

but operates

a. Fuel filter clogged.

2. Engine runs,

erratically.

b. Drain and clean fuel system.

b. Water in fuel.

c. Clean and tighten connections.

c. Loose ignition

connections.

d. Correct intake air leaks.

d. Air leaks in

carburetor con-

nections.

e. Open vent in fuel tank cap.

e. Fuel tank cap

clogged.

f. Check spark plugs. cables and

f. Faulty ignition

system

magneto output per section VIII.

a. Spark plug gap too wide.

3. Engine skips at governed speed.

15).

b. Carburetor out of adjustment.

c. Timing incorrect.

17a).

a. Fuel mixture too lean.

a. Adjust carburetor (para 4-20a).

4. Engine backfires.

b. Improper timing.

17a).

c. Valve sticking.

c. Report trouble to direct support

maintenance.

a. Dirty intake screen, shroud, or

a. Clean engine parts.

5. Engine overheats.

cooling fins.

b. Correct carburetor adjustment

b. Fuel mixture too lean.

c. Improper ignition timing.

17a).

d. Pump defective, causing engine

d. Report to direct support main-

overload.

tenance.

e. Report to direct support main-

e. Valve tappet clearance too tight.

tenance.

a. Impeller damaged.

a. Report to direct support main-

6. Pump is noisy, vibrates, or turns

tenance.

with difficulty.

b. Impeller rubbing against volute in

b. Report to direct support main-

pump.

tenance.

c. Foreign matter in pump.

c. Clean out pump.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |