|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

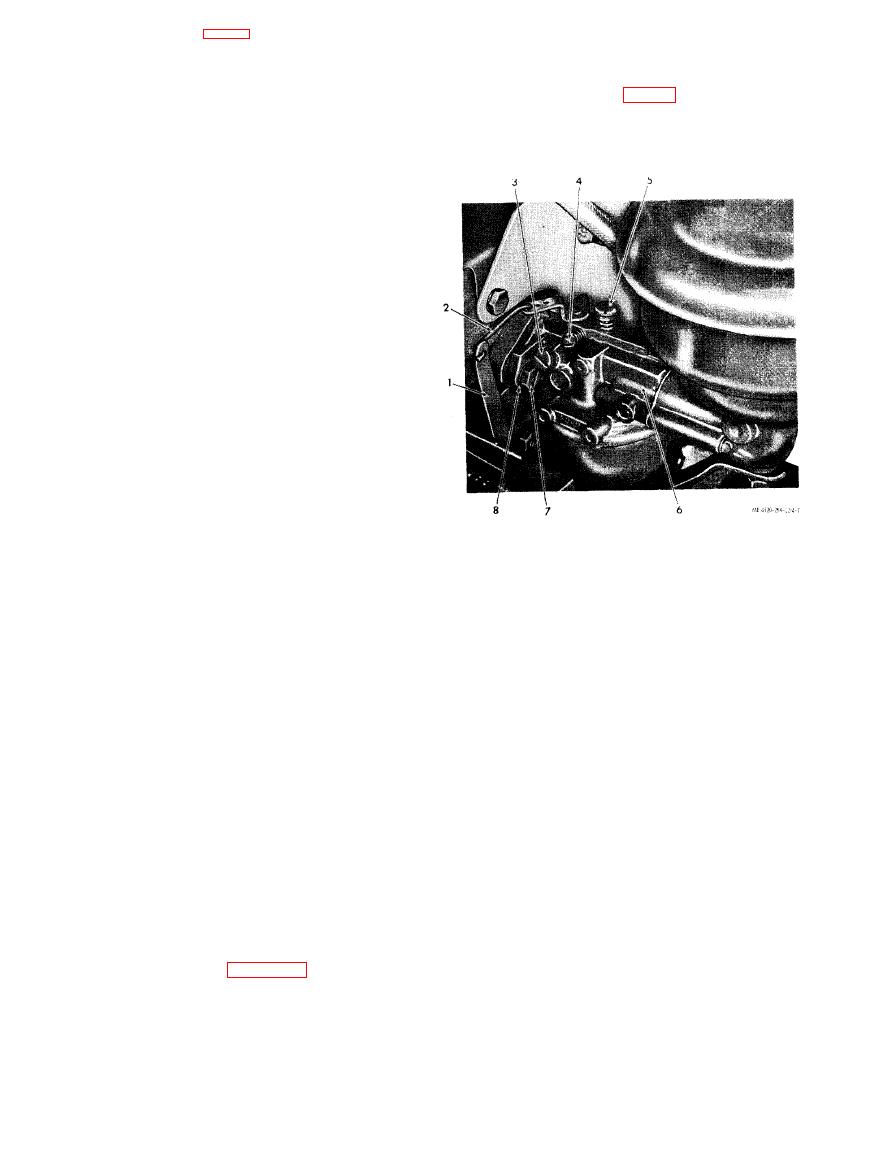

KEY to fig. 4-6:

4-20. Carburetor

a. Adjustment.

1.

Tube nut

(1) With the engine stopped. turn the main

2.

Tube

fuel adjustment needle (5, fig. 4-7) clockwise until

3.

Elbow

4.

Bail

it just bottoms. Do not force the needle against its

5.

Bowl

seat or damage might result. Also turn the idle fuel

6.

Gasket

adjustment needle (3) clockwise until it is seated.

7.

Filter

8.

Housing

9.

Pipe nipple

10.

Inlet strainer

11.

Cap screw

12.

Nut

13.

Strap

14.

Cap screw

15.

Nut

16.

Strap

17.

Fuel tank

18.

Webbing

19.

Fuel tank bracket

b. Cleaning and Inspection.

Warning: The fuel tank is normallly

replaced if damaged. However, if expediency

requires that the fuel tank be repaired by any

method involving heat or flame, steam-clean

the tank thoroughly to assure that all traces of

gasoline are removed before starting repairs.

Failure to purge the tank of all traces of fuel

fumes before applying heat or flame may result

1.

Governor lever

in a severe explosion.

2.

Governor link

(1) Clean all parts with an approved cleaning

3.

Idle fuel adjustment needle

solvent. Flush the fuel line with solvent and blow it

4.

Idle speed adjustment

out with clean, filtered compressed air.

5.

Main fuel adjustment needle

6.

(2) Inspect the fuel tank for cracks, leaks, and

Carburetor

7.

Cap screw

severe dents. Make sure the cap and chain are

8.

Lock washer

present and are in good condition.

(3) Inspect the fuel strainer for a cracked

bowl or body, damaged threads, and distorted bowl

(2) Back out (counterclockwise) the main fuel

bail. Make sure the bowl glass is clear so that the

adjustment needle exactly two turns. Back out the

fuel is visible in the bowl. Check the fuel shutoff

idle fuel adjustment needle one and one-fourth

valve on the fuel strainer housing. Make sure it

turns. This is a preliminary setting.

operates freely and effectively.

(3) Start the engine and allow it to warm to

(4) Inspect the fuel line for cracks, dents,

operating temperature.

damaged tube nuts, clogging, and other damage;

(4) With the engine operating at full throttle

replace the fuel line.

and full load, turn in (clockwise) the main fuel

(5) Inspect the fuel tank straps for cracks,

adjustment needle until the engine starts to slow

distortion, and other damage; replace damaged

down because of a lean fuel mixture. Note the

straps.

position of the screw, then turn out (coun-

(6) Inspect a l l other parts for cracks,

terclockwise) the screw until the engine again starts

distortion, and damaged threads; replace damaged

to slow down, this time from an overly rich fuel

parts.

mixture. Note this setting. Adjust the main fuel

c. Reassembly and Installation.

adjustment needle so that it is positioned midway

(1) Reassemble and install the fuel tank, lines,

between the too rich and too lean settings.

and fittings as shown in figure 4-6.

(5) Allow the engine to operate at this setting

(2) After installation, fill the fuel tank with

and check that the engine operates smoothly as the

the required gasoline and open the shutoff cock.

load is added or decreased.

Check the entire system for leaks. Correct any leaks

before restoring the unit to service.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |