|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-258-34

c.

Reassembly and Installation.

(6) Clearance must be between 0.0008 and

0.0028 inch. If the clearance is not within these limits,

(1) Install the rear oil seal and oil guard as

replace the bearings and recheck the clearance.

directed in paragraph 4-6 c.

(7) Remove and replace the bearings as

(2) Position the thrust plate (24, fig. 4-14)

follows:

on the crankshaft and install the key (23) in the keyway

(a) Remove the bearing cap; remove

of the crankshaft, after making sure that the keyway is

the bearing from the cap.

free of burrs. Press the gear (22) onto the crankshaft.

(b) Install a pin with an angular head

Install the oil thrower (21).

(3) Position the upper half of the main

in the oil hole in the crankshaft bearing journal (fig. 4-

bearings (29, 33, 36, and 39) in the seats in the

16).

(c) Rotate the crankshaft by hand.

crankcase. Position the crankshaft in the bearing shells.

The pin will force the top bearing half out of its seat.

Caution: When installing the crankshaft,

(d) Position the replacement bearing

make sure the timing marks on the crankshaft gear

on the crankshaft bearing journal. Rotate the crankshaft

are alined with the timing marks on the camshaft

by hand. The pin will force the bearing half into position

gear. See paragraph 4-12.

as shown in figure 4-18.

(4) Install the lower half of the main

bearings in the bearing caps (27, 32, 34, and 37).

(5) Check the clearance between the

crankshaft bearing journals and bearings as follows:

(a) Place a piece of plastigage near

the oil hole of the bearing cap.

(b) Position the cap on the block and

secure with the two screws and lock washers. Tighten

the screws to 85 to 95 foot-pounds torque.

(c) Remove the bearing and bearing

cap. Check the bearing journal-to-bearing clearance

indicated by the plastigage (fig. 4-17).

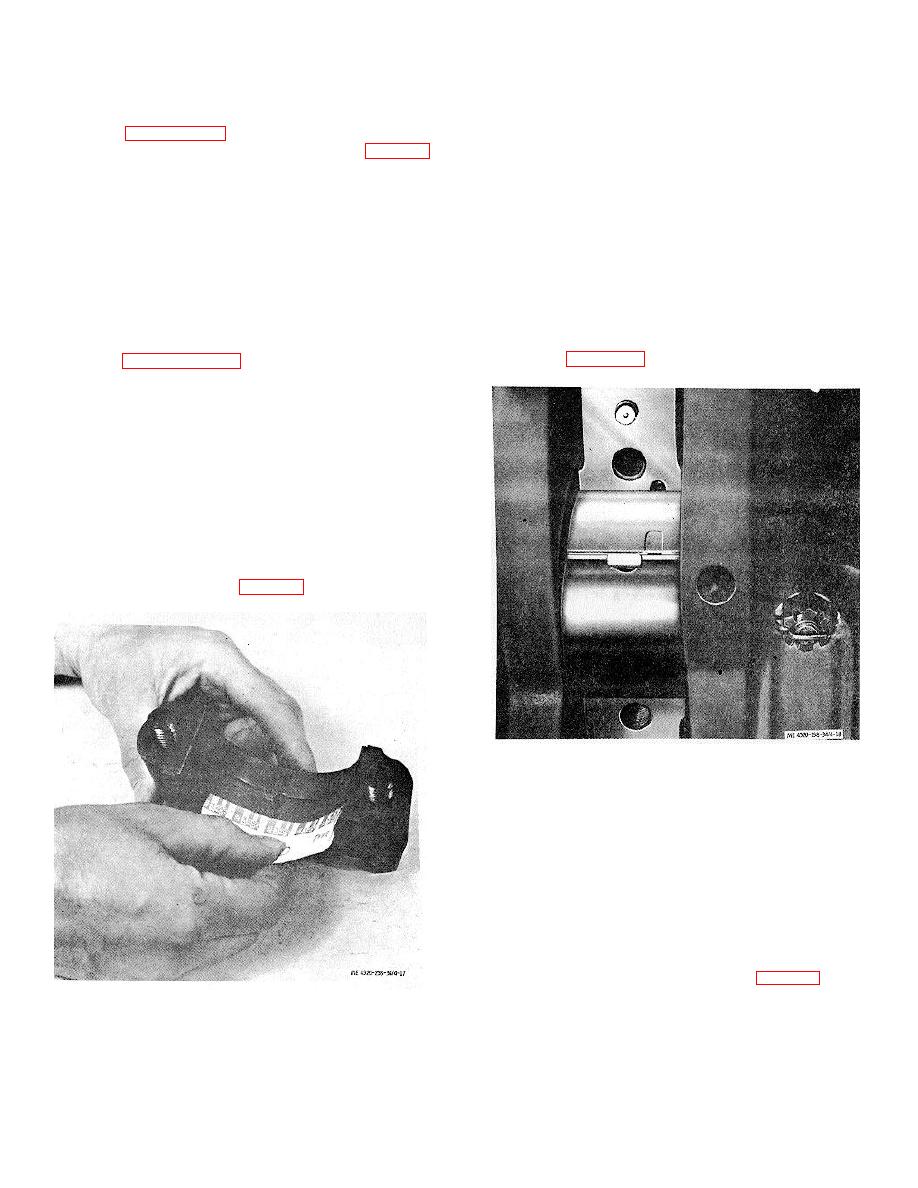

Figure 4-18. Installing upper bearing half, using angular

pin.

(e) Install the replacement bearing

half in the cap. Install the cap.

(8) Check the remaining bearing-to-bearing

journal clearances and replace bearings as necessary.

(9) An alternate method of checking

bearing clearance is as follows:

(a) Oil the bearing and bearing journal

with engine oil.

(b) Position a strip of 0.003-inch feeler

gage, 1/2 inch long, on the bearing cap (fig. 4-19).

Figure 4-17. Checking bearing clearance with

plastigage.

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |