|

|||

|

|

|||

|

Page Title:

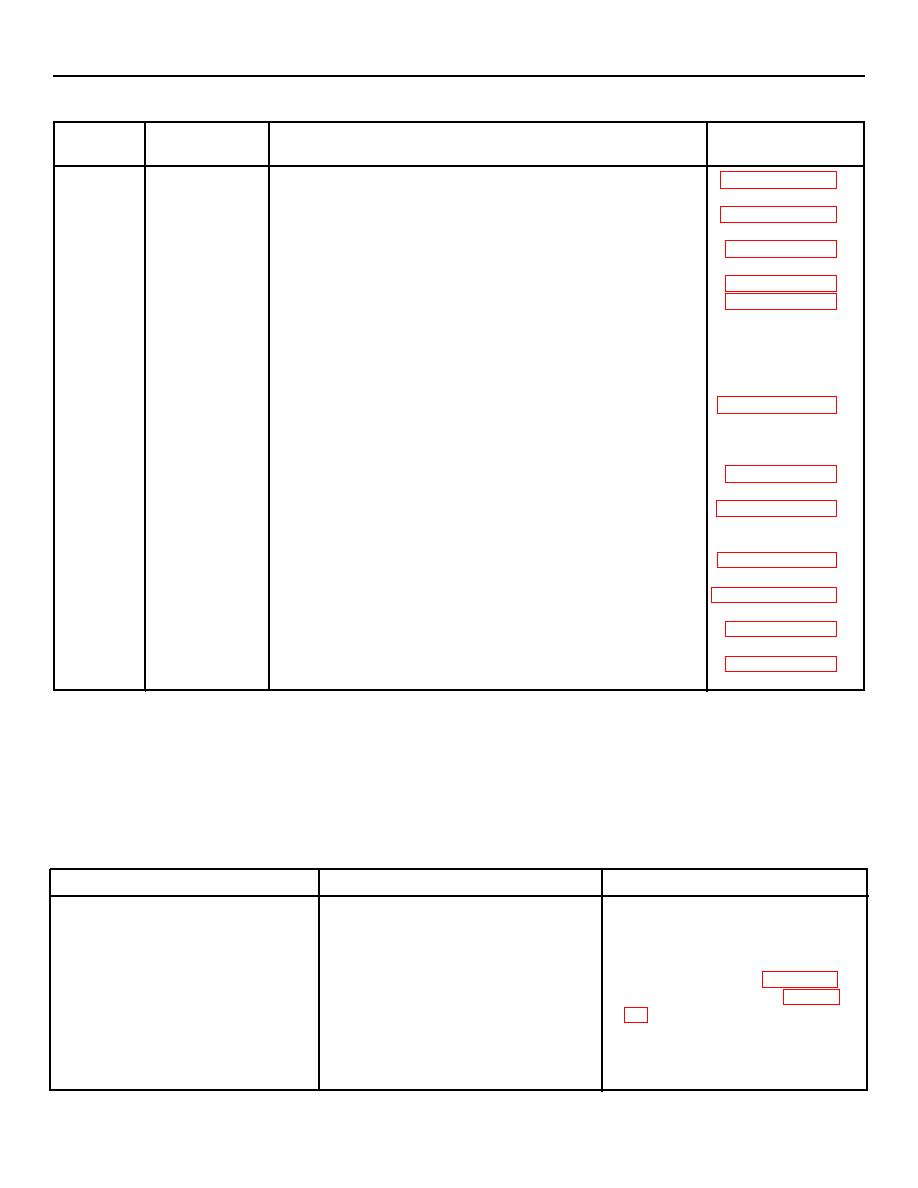

Table 4-1. Preventive Maintenance Checks and Services-continued |

|

||

| ||||||||||

|

|

Monthly Schedule

Organizational Maintenance Category

(or Quarterly)

Sequence

Item to be

Paragraph

number

inspected

Procedures

reference

7

Exhaust system

or leaks are noted.

8

Air cleaner

Check condition of air cleaner element. Replace element or any

other damaged parts.

9

Control panel

Replace inoperative or illegible gages, defective switches, or

damaged controls.

10

Engine housing

Repair or replace damaged housing panels or parts.

11

Fuel lines,

Correct any leaks and replace defective parts. Service fuel

fittings, and

strainer.

strainer

12

Intake and

Check for cracks and damage. Report to direct support if ex-

exhaust

haust leakage is suspected.

13

Spark plugs

Check for cleanliness and proper gap. Clean and regap if nec-

essary. Replace defective plugs.

14

Skid base

Inspect for cracks and distortion. Report damage to direct sup-

port maintenance.

15

Engine starter

Check that starter cranks engine properly. Replace defective

starter.

16

Battery charg-

Check ammeter with engine running. Test components if alter-

ing system

nator fails to provide proper charge rate. Replace defective

alternator or regulator.

17

Magneto

Check breaker point opening. Replace burned points and adjust

point gap.

18

Water pump

Check flow of coolant during engine operation. Replace water

pump if coolant flow is insufficient or if water pump leaks.

19

Engine governor Adjust engine governor if full-throttle operation is not between

2400 and 2500 rpm.

20

Engine

If compression is erratic from cylinder to cylinder, report to

compression

direct support maintenance.

Section VI. TROUBLESHOOTING

correct the malfunction, report the trouble to direct

4-13. General

support maintenance.

This section describes troubles which might occur

4-14. Organizational Maintenance Troubleshooting

during operation of the centrifugal pump, along with

probable causes and corrective actions relating to the

Chart

troubles. Only those malfunctions which are within the

Refer to table 42 for troubleshooting which is allocated

scope of organizational maintenance are included in this

to

the

organizational

level

of

maintenance.

chart. If corrective actions given in this chart do not

Table 4-2. Organizational Maintenance Troubleshooting Chart

Malfunction

Probable cause

Corrective action

1. Starting motor fails to crank

a. Weak or dead battery.

a. Charge or replace battery (para

engine.

4-2c).

b. Poor ground connection.

b. Replace or tighten battery ground

cable.

c. Faulty starter pushbutton.

d. Defective starting motor.

e. Internal engine seizure.

e. Report to direct support mainte-

nance.

2. Engine cranks but fails to start

a. Magneto points not closing.

a. Adjust magneto point gap (para

(no spark).

4-34).

4-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |