|

|||

|

|

|||

|

Page Title:

Operation Under Usual Conditions |

|

||

| ||||||||||

|

|

b. Electrical System. Clean the batteries and

Caution

The oil pressure gage (fig. 2-6)

cables, and inspect for cracked or damaged cases. Be

sure the battery terminals are tight, clean, and lightly

must read above 30 psi. If no oil

pressure is indicated, stop the

greased. Inspect wiring for brittle or broken insulation.

The electrolyte level must be three-eighths inch above

engine immediately and check the

the plates. To prevent the batteries from freezing, see

cause (para 3-15).

that they are kept fully charged.

Caution

Water added to a battery may

freeze unless it is immediately

mixed with the electrolyte by

operating the engine at 1,000 rpm

for 30 minutes.

c. Lubrication. Lubricate the centrifugal pump for

cold weather conditions in accordance with the current

lubrication order (fig. 3-1).

d. Cooling System. Test the coolant with a

hydrometer to insure adequate protection for the lowest

temperature expected. Inspect for leaks and cracks in

hoses and fittings. Frequently inspect the coolant level

in the radiator and add water if it is necessary.

2-15. Operation in Extreme Heat

a. General. Efficient cooling, adequate ventilation

and adequate lubrication are of vital importance for the

operation of the centrifugal pump in extreme heat.

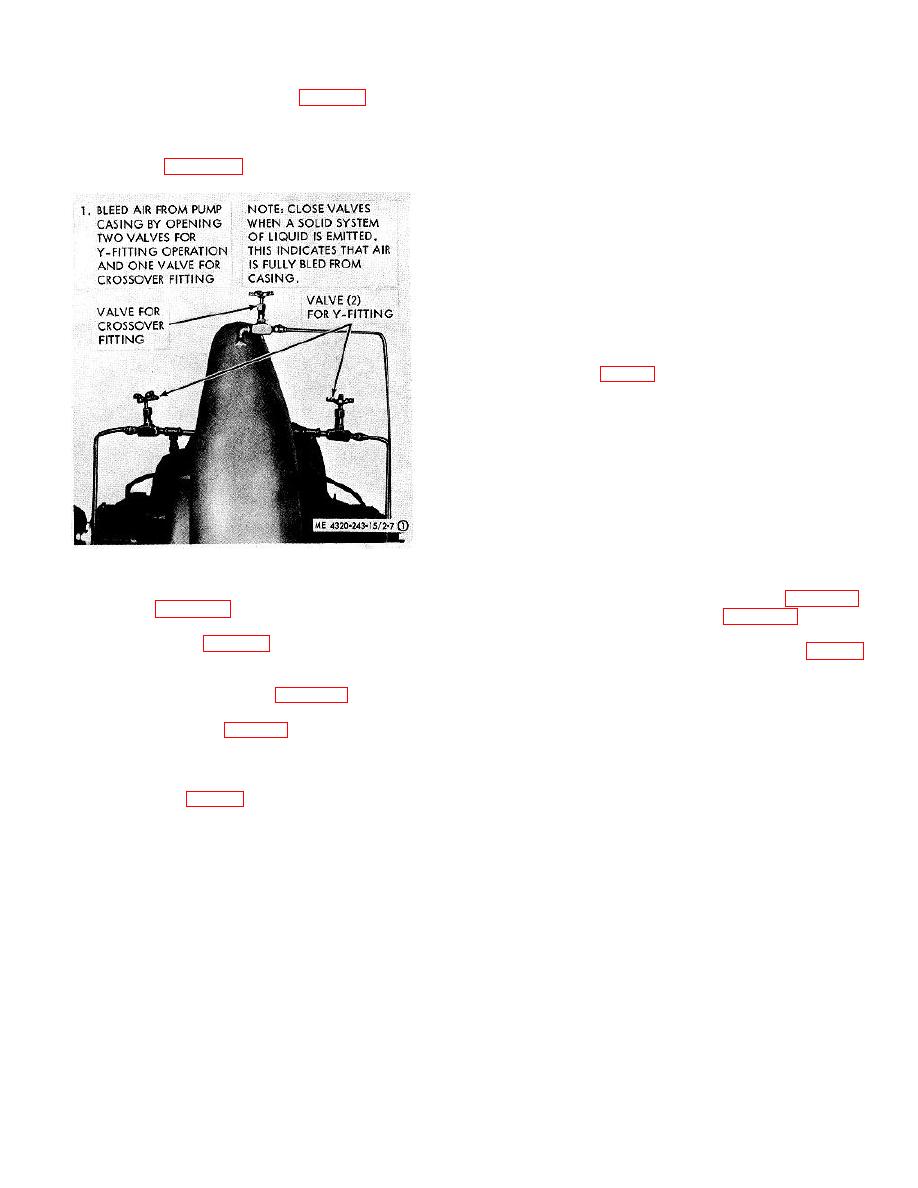

Figure 2-7. Starting the pump assembly.

b. Cooling System. Check the coolant level

frequently and add clean water when necessary. Clean

2-12. Stopping

and flush the radiator at regular intervals (para 3-56).

Keep the V-belts properly adjusted (para 3-58).

b.

Perform the necessary daily preventive

c. Lubrication. Lubricate the centrifugal pump in

maintenance services (para 3-6).

accordance with the current lubrication order (fig. 3-1)

for hot weather operation.

2-13. Operation Under Usual Conditions

d. Batteries. Inspect the electrolyte frequently for

proper level.

b. To operate the pump assembly open the main

e. Indoor Ventilation. Provide adequate ventilation

discharge line valve (fig.

for the radiator. Allow sufficient space around the

pressure.

centrifugal pump for good air circulation.

c.

Performance characteristics under usual

operating conditions are shown in the pump

2-16. Operation in Dusty or Sandy Areas

performance curve (fig. 2-9).

a. General. If the installation is permanent, erect a

protective shield for the centrifugal pump. Dust and

2-14. Operation in Extreme Cold (Below o0 F)

sand shorten the life of equipment and cause

a. Fuel System. Keep the fuel tank full to prevent

mechanical failure. If the installation

condensation of moisture which will freeze and can clog

the fuel lines.

2-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |