|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

10-4320-202-15

tor has a cap to prevent entry of dirt. Replace

conductive to help dissipate static charges

all damaged and missing parts.

which build up in pumping and storage equip-

ment and which can cause arcing that would

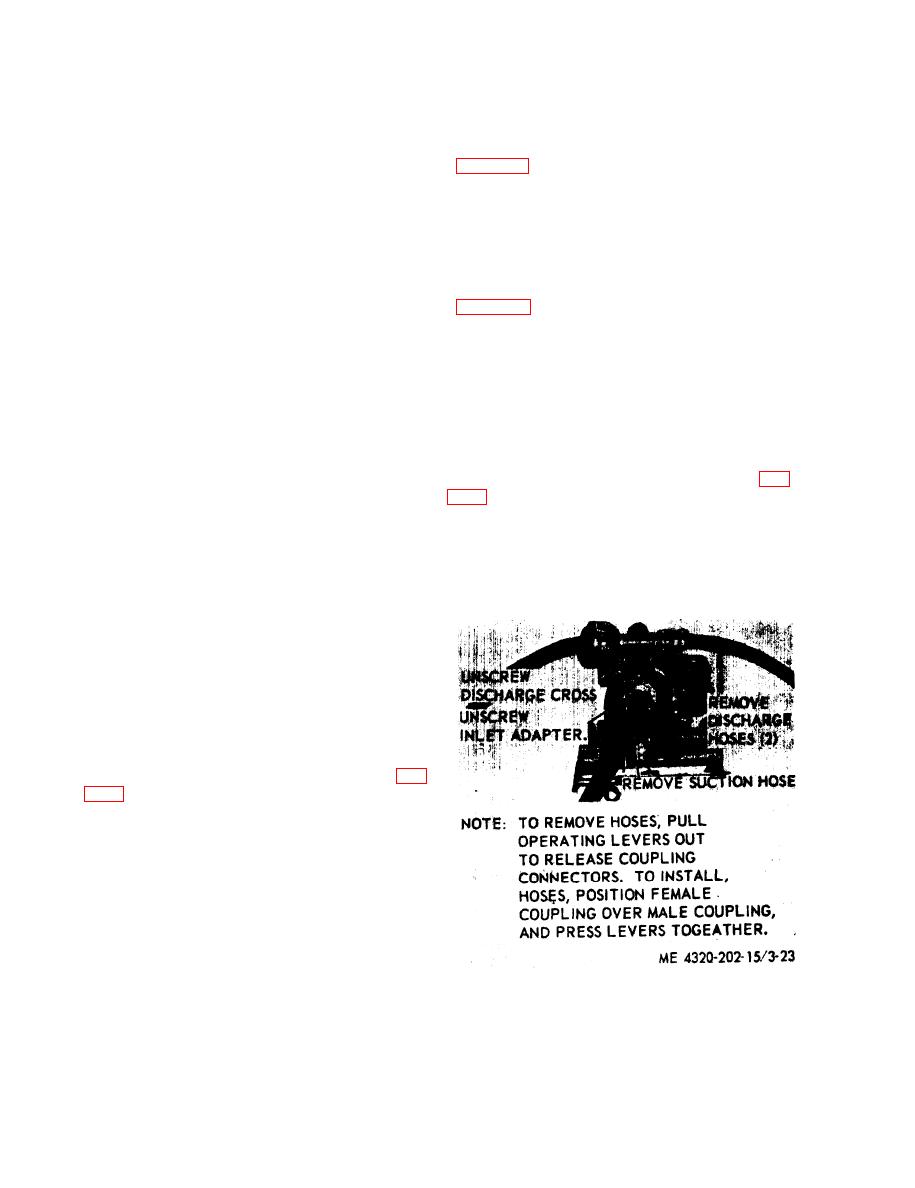

c. Installation. Install hoses and fittings

ignite fumes of volatile fuels.

b. Discharge Hose. Two 50 foot discharge

hoses are provided, each fitted with a male

3-45. Nozzles

quick coupling connector at one end and a

a. Removal. Pull out on the coupling oper-

female quick coupling connector at the other

ating levers to remove the nozzle from the

end. The female connectors engage the male

hose.

connectors on the discharge tee. The male con-

b. Disassembly. Disassemble the nozzles

nectors engage the female on the discharge

nozzles. The hoses have flexible walls. They

are electrically conductive to help dissipate

c. Cleaning and Inspection.

static charges which build up in the pumping

(1) Clean all park with approved clean-

and storage equipment.

ing solvent. Dry thoroughly.

c. Nozzles. Two discharge nozzles are pro-

(2) Inspect the nozzle parts for cracks,

vided for use with the two discharge hoses

distortion, worn or damaged threads, and other

permitting the dispensing of fuel from either

damage. Make sure the ground cable and pinch-

or both discharge hoses. The nozzles are non-

type ground connector are attached and in good

automatic shut-off type and have female quick

condition.

coupling connectors. Each nozzle has a ground

cable to electrically ground the equipment, pre-

venting static charges from arcing and igniting

e. Installation. Pull out on the coupling

fumes of the flammable fuels.

operating lever and position the nozzle on

d. Fittings. The discharge tee is screwed into

the hose. Push in on the operating levers to

the top of the pump housing and has a plug

join the parts.

at the top which can be used for pump priming.

The tee provides two discharge connections

from the engine end. The male intake adaptor

is the quick coupling type and is screwed into

t h e intake port of the pump housing. All

female couplings are provided with plugs and

all male couplings are provided with caps to

prevent the entry of dirt when the associated

port is not coupled.

3-44. Hoses and Fittings

b. Cleaning and Ispection.

(1) Inspect suction hoses for cracks, leaks,

signs of deterioration, worn or damaged fit-

tings, collapsed walls and other damage.

(2) Inspect discharge hoses for cracks,

leaks, signs of deterioration, worn or damaged

fittings and other damage.

( 3 ) Inspect discharge tee and inlet

adapter for damage which could affect the

sealing characteristics of the part.

(4) Check that every female connector

Figure 3-23. Hoses and fittings, removal and

has a mating plug and that every male connec-

installation.

3-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |