|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

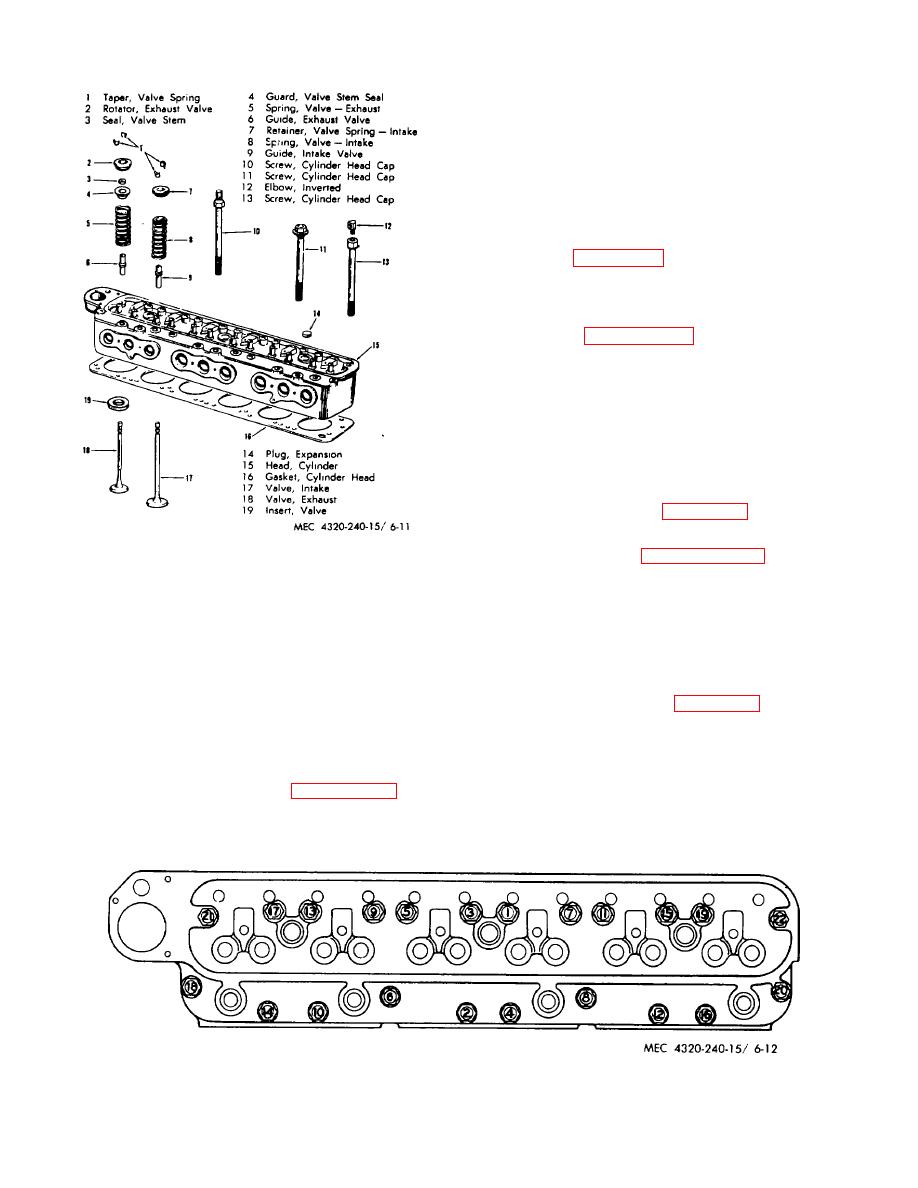

(1) Position cylinder head on cylinder block

using a new cylinder head gasket. A small amount of

cement may be used around water and oil holes of the

cylinder head ,i U' to provide a tight seal at those points.

Never install cylinder head without closing spark plug

holes. This is important because small washers or nuts

may find their way into the combustion chamber and

cause serious damage. Secure the cylinder head with

the cylinder head hold down capscrews. Tighten the

capscrews a little at a time and in the sequence

indicated in figure 6-12 continue tightening in that

rotation until all cylinder head capscrews are tightened

to 98 to 100 ft-lbs torque.

(2) Complete cylinder installation in reverse

order noted in paragraph 6-12b.

6-13. Valves, Seats, and Guides

a. General. The valves are positioned in the

cylinder head. They are operated by the cam shaft and

are so timed as to let in a mixture of gasoline and air at

just the right instant. They also serve in exhausting the

burned gas.

(1) Refer to paragraph 6-12b and remove

Figure 6-11. Cylinder head-exploded view.

cylinder head.

(2) The end of each valve stem is fitted with

a shallow steel retainer that accommodates the end of

(3) Inspect the cylinder head for cracks,

the valve spring, and is held to the stem by a pair of

breaks, and warpage. Check the flatness of the cylinder

split tapers. The locking tapers must be removed before

head with a straight edge and feeler gage in three

the valve can be withdrawn. To release the lock from

positions lengthwise and five positions crosswise. The

the recess in the spring retainer, it is necessary to use a

maximum permissible warpage is 0.004 inch low in the

spring compressor, refer to figure 6-13 and press down

center lengthwise, gradually decreasing toward the

until the tapers fall free.

ends, or 0.003 inch crosswise in localized low spots.

Replace a cracked, broken, or warped cylinder head.

(3) Lift each valve from the cylinder head.

Place them in order in a rack to assure that each will be

reassembled in the same valve guide from which it was

e. Reassembly.

Refer

to

and

removed.

reassemble cylinder head.

f. Installation.

Figure 6-12. Cylinder head tightening sequence.

6-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |