|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-234-34

one revolution. Hold pressure against the flywheel to

flywheel housing mounting bolts and tap the housing

into its proper position with a soft hammer. Tighten the

eliminate end play. If runout exceeds 0.008 inch

(0.0200 cm), clean the mounting surfaces of the

bolts and recheck eccentricity of the housing bore. If

the housing cannot be brought into true position, replace

flywheel housing and the block. Recheck flywheel

the housing.

housing runout. If the runout is still not within limits,

replace the flywheel housing.

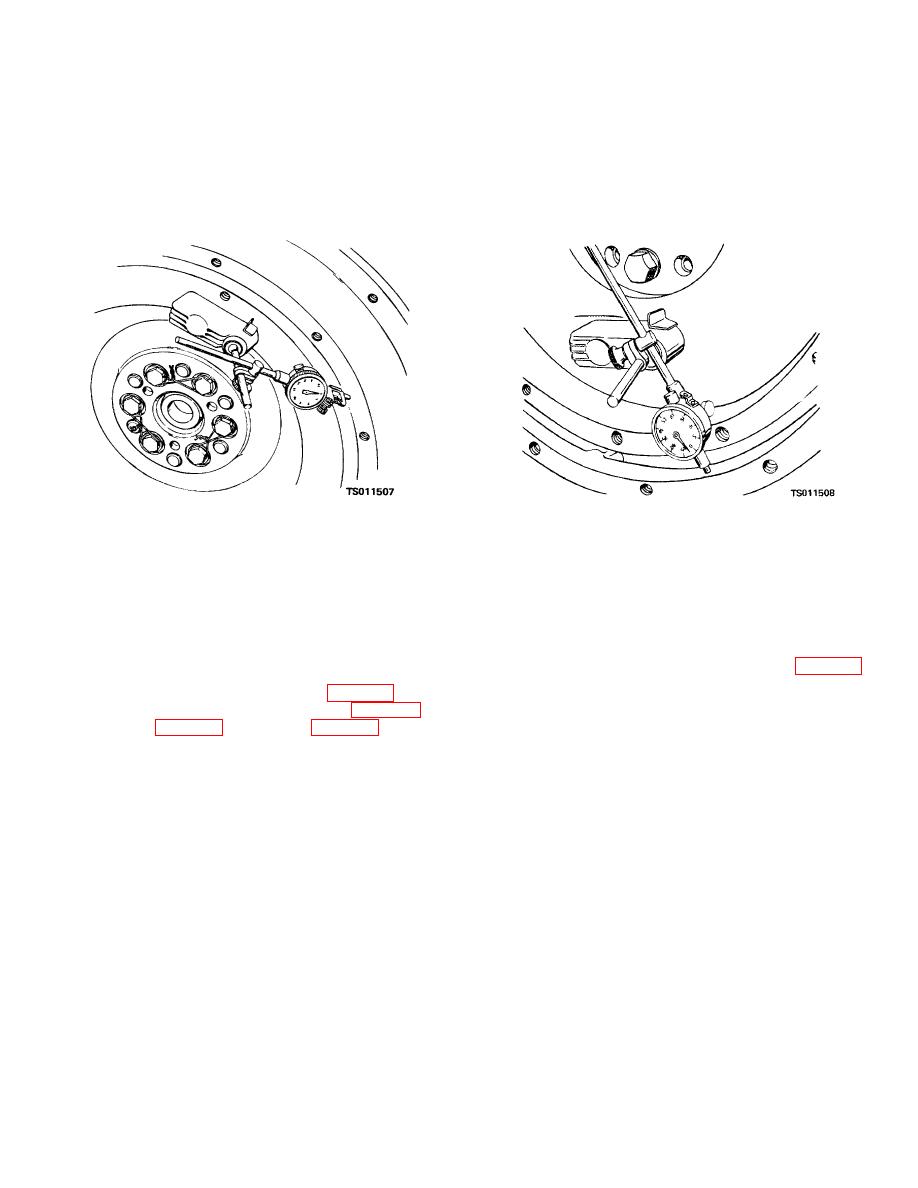

Figure 4-11. Checking flywheel housing runout.

Figure 4-12. Checking flywheel housing

eccentricity.

(6) Check eccentricity of the flywheel housing

bore by mounting a dial indicator so that it indicates

(3) Ream the ridge of the top of each cylinder

bore with a standard ridge reamer.

Blow metal

4-9. Pistons and Connecting Rods

fragments from the cylinder with compressed air.

a.

Removal and Disassembly.

With the engine

mounted on an engine overhaul stand, proceed as

(4) Remove the two cotter pins (10, fig. 4-13)

follows:

and nuts (11), that secure a bearing cap (13) to a

(1) Remove the cylinder head (para 4-3a).

connecting rod (20); remove the cap and bearing shells

(2) Remove the engine oil pan (para 4-5a)

(14).

and oil pump (para 4-6a). the bore (fig. 4-12); rotate

the engine through one revolution. If the housing bore is

eccentric more than 0.008 inch (0.0200 cm), loosen the

4-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |