|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-234-34

to 15 to 20 foot-pounds torque.

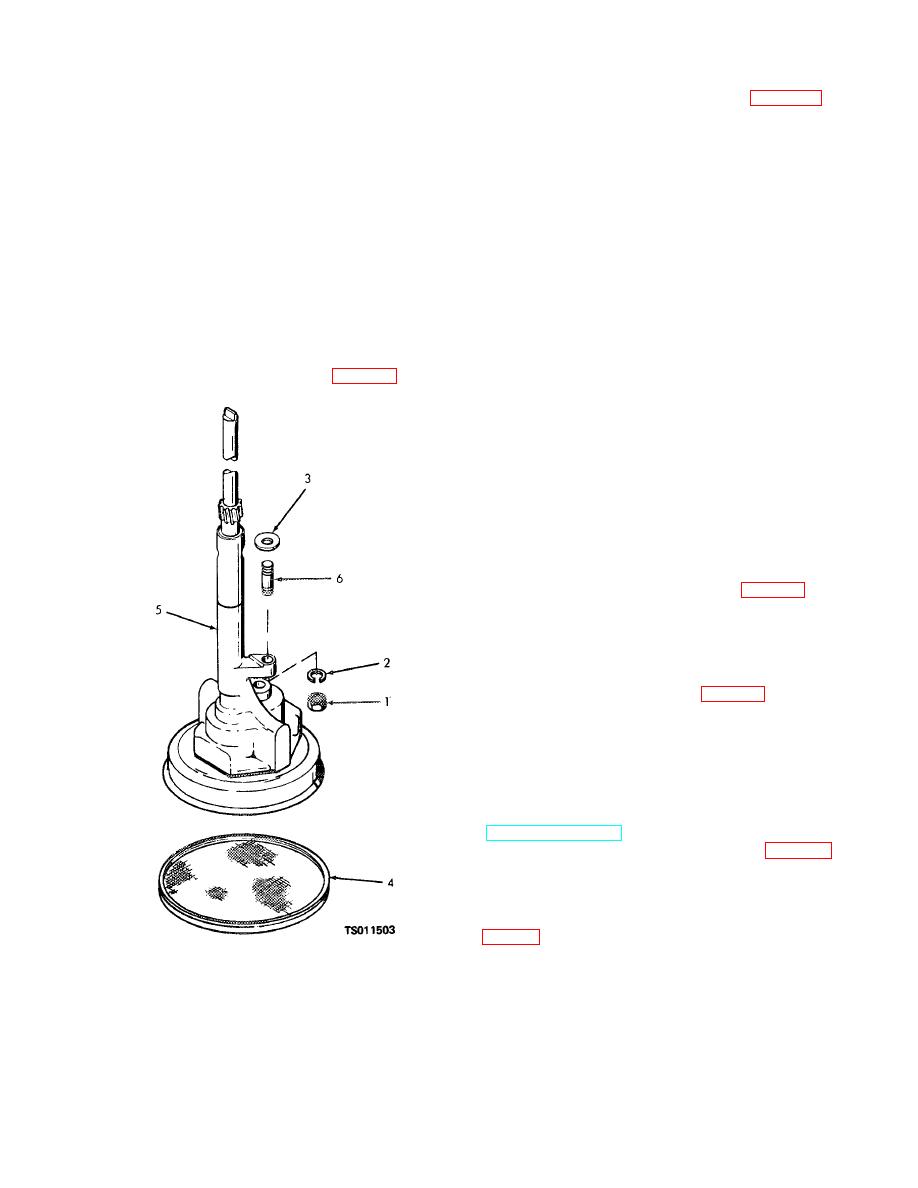

(2) Remove the nut (1, fig.

4-7) and

(5) Position the gaskets (7) on the oil pan (6).

lockwasher (2) securing the engine oil pump to the

Install the oil pan and gaskets on the engine block;

bearing cap. Remove the oil pump and flat washer (3).

secure with the 18 assembled washer screws (5).

(3) Remove the screen (4) from the bottom of

Tighten the screws to 12 to 16 foot-pounds torque.

the oil pump (5).

(6) Coat the male threads of the elbow (4)

b. Cleaning and Inspection.

with thread sealing compound and install the elbow in

the drain pan. Coat the male threads of the nipple (3)

WARNING

with thread sealing compound and install the nipple in

Clean all parts in a well-ventilated area.

the elbow. Install the coupling (2) on the nipple, and

Avoid inhalation of solvent fumes and

install the oil drain plug (1) in the coupling.

prolonged exposure of skin to cleaning

solvent. Wash exposed skin thoroughly.

4-6. Engine Oil Pump

Dry cleaning solvent (Fed. Spec. P-D-680)

used to clean parts is potentially dangerous

a. Removal.

to personnel and property. Do not use near

open flame or excessive heat. Flash point of

(1) Remove the engine oil pan (para 4-5).

solvent is 100 F. to 138 F. (38 C. to 59 C.)..

(1) Clean all parts with dry cleaning solvent

(Fed. Spec. P-D-680). Allow all parts to dry thoroughly

before reinstallation.

(2) Inspect the screen for holes, clogging, and

distortion. Replace a damaged screen.

(3) Check the fit of the drive shaft in the

pump body. There shall be no excessive play. Replace

the oil pump if the shaft is damaged, or if the play is

excessive.

c. Installation.

(1) Install the screen (4, fig. 4-7) on the

bottom of the oil pump (5).

(2) Position the washer (3) and oil pump (5)

on the main bearing so that the drive gear engages the

toothed portion of the camshaft. Secure the pump with

the nut (1) and lockwashers (2).

(3) Install the oil pan (para 4-5).

4-7. Gear Cover

a. Removal and assembly.

(1) Remove the governor from the engine

(para 34).

(2) Remove the water pump from the engine

(TM 5-4320-234-12, para 4-31).

(3) Remove the starting jaw (1, fig. 4-13) and

collar (2) that secure the pulley (3) to the front end of the

crankshaft; remove the pulley and key (4) from the

crankshaft.

(4) Remove the capscrews (1, 3, 6, and 10,

1. Nut

4. Screen

lockwashers (2, 9, and 12), and copper washers (4 and

2. Lockwasher

5. Engine oil pump

7) that secure the gear cover (14) to the engine block;

3. Flat washer

6. Stud

remove the gear cover and gear cover housing gasket

(15) from the front end plate (19).

Figure 4-7. Engine oil pump installation.

4-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |