|

|||

|

|

|||

|

Page Title:

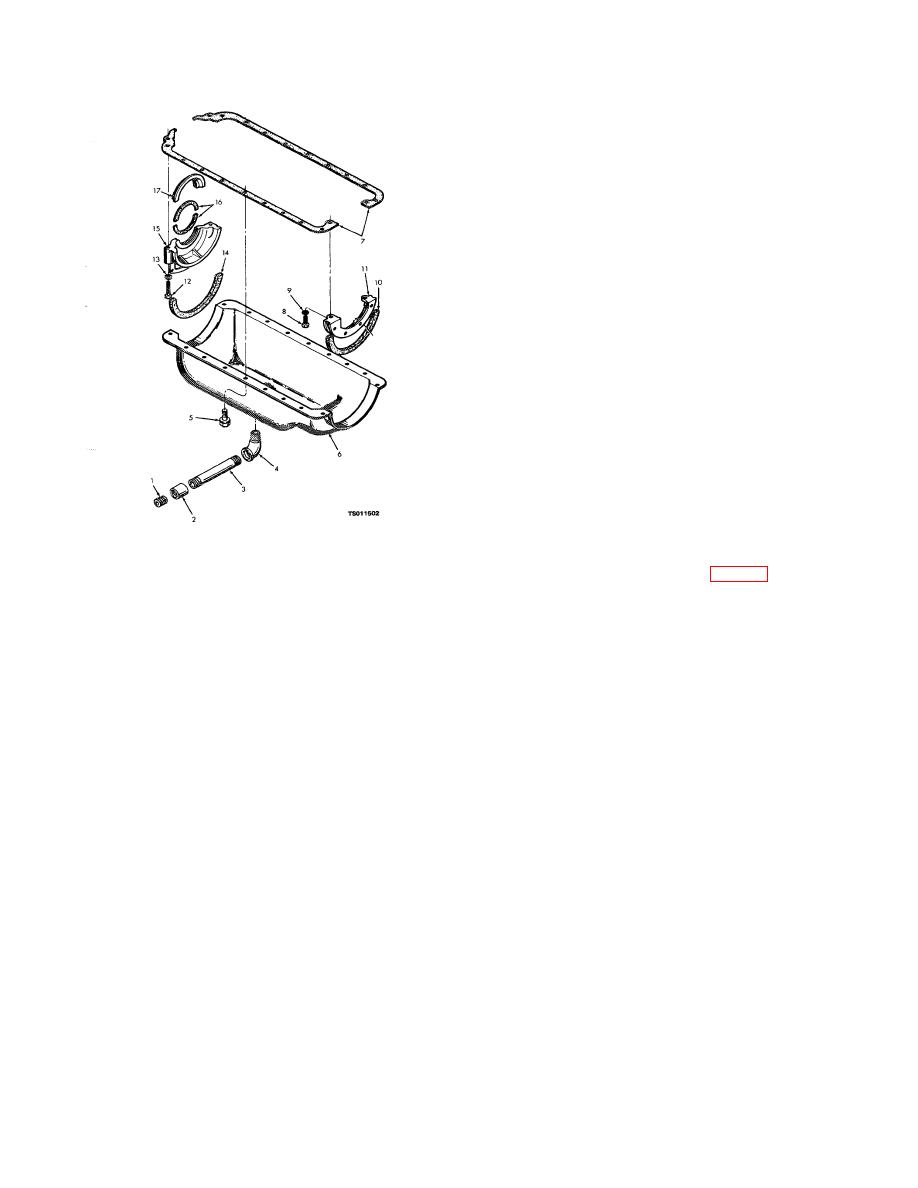

Figure 4-6. Oil pan and filler blocks, exploded view. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

WARNING

Clean all parts in a well-ventilated

area. Avoid inhalation of solvent

fumes and prolonged exposure of

skin to cleaning solvent. Wash

exposed skin thoroughly.

Dry

cleaning solvent (Fed. Spec. P-D-

680) used to clean parts is

potentially

dangerous

to

personnel and property. Do not

use near open flame or excessive

heat. Flash point of solvent is 100

F. to 138 F. (38 C. to 59 C.).

(2) Clean all remaining parts with cleaning

solvent (Fed. Spec. P-D-680); dry thoroughly.

(3) Inspect the oil pan for cracks, severe

dents, holes, damaged threads, and other damage;

replace a defective oil pan.

(4) Inspect the filler blocks for cracks,

distortion, and other damage; replace damaged filler

blocks.

1.

Oil drain plug

c. Installation.

2.

coupling

3.

Nipple

(1) Install the seal (16, fig. 4-6) into the rear

4.

Elbow

filler block (15) and oil guard (17) as follows:

5.

Assembled washer screw

(a) Flatten the jute seal in a vise or with a

6.

Oil pan

7.

Oil pan gasket

hammer until the seal fits into the groove in the filler

8.

Capscrew

block or oil guard.

9.

Lockwasher

(b) Roll the seal into the oil guard or filler

10.

Front filler block seal

block groove with a round object.

11.

Front filler block

12.

Capscrew

(c) Trim the seal 0. 020 to 0. 030 inch (0.

13.

Lockwasher

0500 to 0. 0750 cm) above the flat surface of the oil

14.

Rear filler block seal

guard or filler block, using a sharp knife or razor blade.

15.

Rear filler block

Make sure the cut is parallel to the flat surface of the

16.

Oil guard seal

17.

Rear oil guard

casting.

Figure 4-6. Oil pan and filler blocks, exploded view.

(2) To replace the neoprene seals (10 and

14) on the filler blocks (11 and 15), make sure the

(2) Remove the 18 assembled washer screws

contact surface is free of cement, dirt, and oil. To hold

(5) that secure the oil pan (6) to the block; remove the

the seal in place for assembly, use a small spot of

oil pan and gaskets (7).

nonhardening cement in the center of the contacting

(3) Remove the two capscrews (8) and

surface before you insert the seal into the groove. No

lockwashers (9) that secure the front filler block (11) to

other cement is required.

the block; remove the filler block and seal (10).

(3) Lubricate all seals with engine oil. With

(4) Remove the two capscrews (12) and

the crankshaft in place, the assembled rear oil guard

lockwashers (13) that secure the rear filler block (15) to

(17) and jute seal (16) can be rolled into place around

the block; remove the filler block and seal (14), oil guard

the crankshaft. Position the assembled rear filler block

seal (16) and oil guard (17).

(15) and seal (14) on the engine block; secure with the

two capscrews (12) and lockwashers (13). Tighten the

b. Cleaning and Inspection.

capscrews to 15 to 20 foot-pound torque.

(1) Discard and replace gaskets and seals.

(4) Position the front filler block (11) and seal

(10) on the engine block; secure with the two capscrews

(8) and lockwashers (9). Tighten the capscrews

4-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |