|

| |

TM 55-2915-335-30&P

2-22. PUMP-END MOTOR BEARING - lNSPECT/REPLACE

2-22

This task covers: Replacement of pump cartridge impeller housing motor bearing.

INITIAL SETUP

Tools:

Aircraft Electrician’s Tool Kit, NSN 5180-00-323-4915

Bearing Installation Tool, Item 1, Appendix D

Pin Punch, Straight, 3/8 inch Dia.,

NSN 5120-00-273-0001

Reamer (Item 1, Appendix B, Sec. III)

Press, Arbor, Hand Operated, 1/2 Ton Pressure,

NSN 3444-00-243-2654, or equivalent

Drill Press, Bench Type, 1/2 inch capacity,

NSN 3413-00-529-0809, or equivalent

Plug Gage, Reversible, Cylindrical (Item 2,

Appendix B, Sec. III)

Material/Parts:

Dry Cleaning Solvent, NSN 6850-00-274-5421

Personnel Required:

66-Series Technical Inspector

68D Powertrain Repairer

Equipment Condition:

Brush holder assembly removed from impeller housing

PARA 2-20

Pump cover and inlet seal removed from impeller housing

PARA 2-21

1. INSPECTION

a.

b.

c.

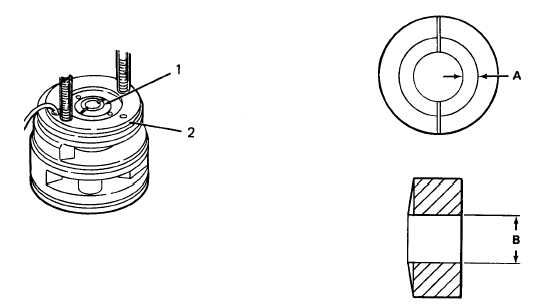

Check pump-end bearing (1) in impeller housing (2) for cracks or chips. If bearing is cracked or chipped, re-

place bearing.

With 6 inch (152,4 mm) scale measure width A of bearing thrust face. If thrust face is more than 1/16 inch

(1,60 mm), replace bearing.

Using plug gage (Item 2, Appendix B, Section III) check bearing bore diameter B. If 0.3145 NO GO gage

passes through bearing, replace bearing.

GO TO NEXT PAGE

2-76

|