|

| |

TM 55-2915-335-30&P

2-22. PUMP-END MOTOR BEARING - lNSPECT/REPLACE (Cont)

2-22

2. REMOVAL

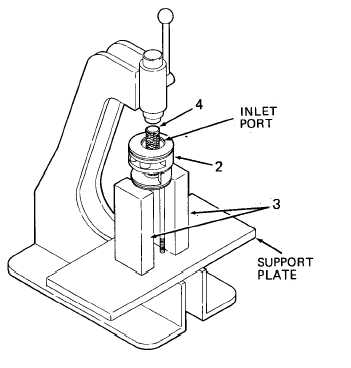

a. Set impeller housing (2) on arbor press, as shown.

Use spacer blocks (3) to keep motor mounting

studs off of support plate. Spacer blocks must not

prevent bearing (1) from being pushed out of

housing. Look underneath housing (2) to check

for clearance between blocks and bearing.

Check that pin punch is not in contact

with impeller housing when pressing bear-

ing out. Failure to position punch cor-

rectly may result in permanent damage to

impeller housing.

b. Place 3/8 inch (10 mm) diameter drive pin punch

(4) in housing inlet port. Position drive end of

punch on back side of bearing (1). Make sure that

punch passes through center bore of bearing seat.

c. Bring arbor down to meet pin punch (4). Line up pin punch to drive bearing (1) straight out of bearing seat.

Double check placement of punch. Press out bearing.

3. INSTALLATION

Compressed air aimed at the skin can cause serious injury or death.

Wear goggles and never use over 30 psi (207 KPa) of compressed air

for cleaning.

Cleaning solvent can be hazardous to your health. Use solvent only

in well ventilated areas. Avoid breathing solvent vapors. Do not use

solvent near an open flame or other source of high heat. Always wear

gloves, apron, and goggles when using cleaning solvent. Store solvent

in approved metal container only.

a. Blow out debris from bearing seat with compressed air, 30 psi (207 kPa) maximum. Wipe out bearing bore with

dry cleaning solvent (Item 7, Appendix C) and a clean soft cloth.

GO TO NEXT PAGE

2-77

|