|

| |

TM 55-2915-335-30&P

2-19. IMPELLER - lNSPECT/REPAIR (Cont)

2-19

3. REPAIR

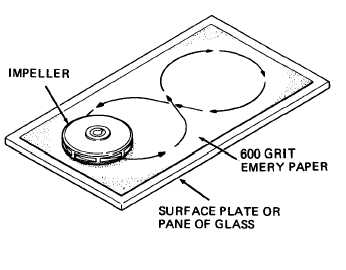

a. Place a sheet of 600 grit wet or dry emery paper on

an inspection surface plate or pane of glass. Place

b.

c.

d.

e.

f.

impeller seal surface down on emery paper.

Apply light and even pressure on impeller drive

boss with index finger.

Lap seal surface by sliding impeller across emery

paper in a figure 8 path. Make only 3 or 4 passes

before checking surface.

When grooves are gone, wipe off surface plate

with a clean cloth. Replace sandpaper with plain

bond paper. Repeat lapping operation on paper to

polish the seal surface to a mirror finish.

Visually check seal surface condition. Surface must

reflect light evenly.

After lapping, check impeller height with an out-

side caliper per Step 1 of INSPECTION. If impel-

ler height is less than 0.585 inch (14,85 mm), im-

peller cannot be reused.

NOTE

FOLLOW-ON Maintenance: Install impeller, armature, and

field tube assembly (paragraph 2-18).

END OF TASK

2-66

|