|

| |

TM 55-2915-335-30&P

2-19. lMPELLER-lNSPECT/REPAIR (Cont)

2-19

2. INSPECTION

a.

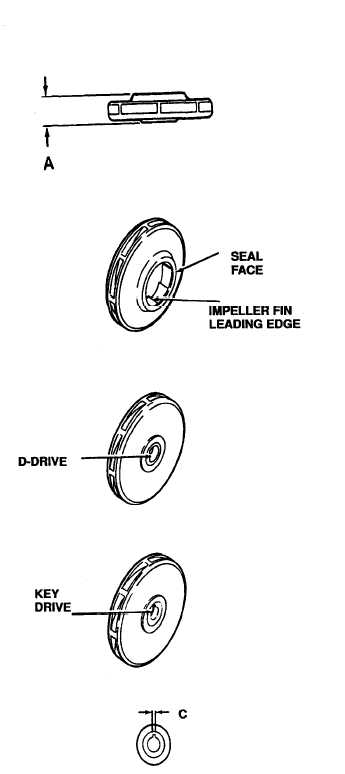

Use an outside caliper to inspect impeller height,

dimension A. If impeller height is less than 0.585

inch (14,85 mm), replace impeller.

b. DELETE.

c.

Visually inspect leading edges of impeller fins.

Leading edges should be sharp. A small amount of

chipping on leading edges is acceptable. Replace

impeller if fin edges are blunt or damaged.

NOTE

If key-drive type impeller is being

inspected, inspect drive boss per Step e

below. Key-drive type impeller and

armature are obsolete. If key-drive type

impeller is defective, both impeller and

armature must be replaced.

d. Visually check impeller D-drive. If flat edge of

“D” is curved or deformed, replace impeller.

e.

Measure impeller key slot width, dimension C.

Using a feeler gage, take measurement at inside

edge of slot near the shaft bore. If key slot width

exceeds 0.067 inch (1,70 mm), replace both arma-

ture and impeller. The key slot width can also be

checked with a No. 50 drill. If shank of a No. 50

drill can be inserted into key slot, impeller slot is

worn. Replace both impeller and armature.

f. Inspect impeller seal face surface for wear. If sur-

face is worn dull or grooved, lap impeller as

instructed in REPAIR procedures.

GO TO NEXT PAGE

Change 2

2-65

|