|

| |

TM 55-2915-335-30&P

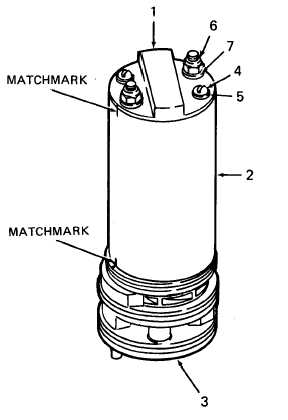

2-16. MOTOR COVER - lNSPECT/REPLACE

2-16

This task covers: Removal and installation of the motor cover. It also covers replacement of the motor cover bearing.

INITIAL SETUP

Tools:

Aircraft Electrician’s Tool Kit, NSN 5180-00-323-4915

Bearing Installation Tool, See Appendix D

Reamer (Item 1, Appendix B, Section III)

Pin Punch, Straight, 5/16" Dia., NSN 5120-00-293-0793

Torque Wrench, 30-150 in-lb, NSN 5120-00-542-4489,

or equivalent

Press Arbor, Hand Operated, 1/2 Ton Pressure,

NSN 3444-00-243-2654, or equivalent

Brush, Soft Bristle, Cleaning

Drill Press, Bench Type, 1/2 inch capacity,

NSN 3413-00-529-0809, or equivalent

Plug Gage, Reversible, Cylindrical

(Item 2, Appendix B, Section III)

Materials/Parts:

White Petrolatum, NSN 6505-00-133-8025

Dry Cleaning Solvent, NSN 6850-00-274-5421

Nut, Self-Locking, NSN 5310-01-210-7300

Personnel Required:

68F Aircraft Electrician

68D Aircraft Powertrain Repairer

66-Series Technical Inspector

Equipment Condition:

Pump cartridge removed from pump and housing as-

sembly PARA 2-10

1. REMOVAL

a.

b.

c.

d.

NOTE

To make sure that cartridge goes back

together correctly, matchmark the as-

sembly before loosening hex nuts. Do not

use scribe on sealing surfaces.

Matchmark motor cover (1) to field tube (2) with

scribe. Matchmark field tube (2) to cartridge hous-

ing (3).

Remove machine screws (4) and lockwashers (5).

Remove and throw away self-locking nuts (6).

Remove flat washers (7).

If cover bearing is chipped during cover

removal, chip may fall into motor. This

may cause binding or failure of pump

motor.

To prevent chipping cover bearing, lift motor

cover (1) straight up from field tube (2). Rocking

cover may cause bearing to chip.

GO TO NEXT PAGE

2-44

|