|

| |

TM 55-2915-335-30&P

2-15. PUMP HOUSING / MOUNTING FLANGE - lNSPECT/REPAIR (Cont)

2-15

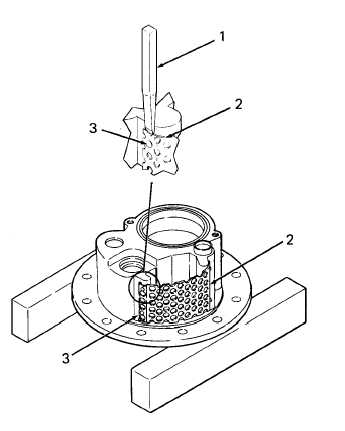

3. REPLACE INLET STRAINER

a.

b.

c.

d.

e.

f.

NOTE

Remove strainer only if found defective in

inspection procedure, paragraph 2.d.

Place parallel blocks under mounting flange to

support housing.

Position tip of 1/4 inch cold chisel (1) or small

sharp screwdriver between inlet screen (2) and

housing next to drive screw head (3). Tap chisel

with hammer to force drive screw out of housing.

Push inlet screen (2) back and grip screw head (3)

with small diagonal cutters. Turn drive screw (3)

counterclockwise. Remove and discard drive

screws.

New inlet screens (2) are flat. Form new inlet

screen to fit pump housing. Hold one end in place

on housing. Apply thumb pressure to form bottom

edge of screen to mounting surface.

Align inlet screen (2) with mounting holes in pump housing. Bottom edge of screen must meet or extend below

shutoff valve seating surface. If mounting holes do not line up with screen holes, drill new mounting holes in

housing. Use No. 43 drill. Drill mounting holes 1/4 inch (6,4 mm) deep.

Apply one drop of locking compound (Item 5, Appendix C) to drive screw (3) threads. Lineup inlet screen (2)

with housing. Place drive screws in mounting holes. Tap drive screws into housing until seated.

NOTE

FOLLOW-ON MAINTENANCE: Install canister on pump housing

(paragraph 2-11).

END OF TASK

2-43

|