|

| |

TM 55-2915-335-30&P

2-15. PUMP HOUSING / MOUNTING FLANGE - lNSPECT/REPAIR (Cont)

2-15

c.

d.

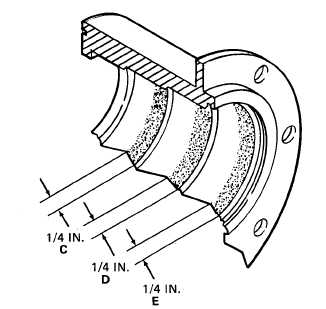

Using a flashlight visually inspect cartridge bore

surfaces in pump housing for burrs, scratches, or

nicks. Preformed packings seat at three bore loca-

tions C, D, and E. Each one is 1/4 inch (6,4 mm)

from edge of bore chamfer as shown in illustra-

tion. If a defect is found on any of the three seal-

ing surfaces the defect must be removed flush with

surrounding surface. Repair and inspect cartridge

bore as follows

(1)

(2)

(3)

(4)

On outside of surfaces C, D, or E it is only

necessary to remove sharp edges from

defects. This will prevent packings from be-

ing cut or damaged when cartridge is in-

serted.

Within sealing areas C, D, or E defect must

be completely removed flush with surround-

ing area.

Use 500 or 600 grit, wet or dry, emery paper moistened with water and polish bore diameter until either

the sharp edges or entire raised portion of defect is removed.

Lightly run your finger around the entire bore area and make sure you do not feel any defects per steps (1)

and (2) above. After you are satisfied with the finish use a clean cloth moistened in cleaning solvent to

clean inside of bore.

Inspect for torn or dented inlet strainer. If torn, replace strainer as instructed in the following paragraphs. If

dented, open and close shutoff valve. Check that dented strainer does not contact shutoff valve. If shutoff valve

touches dented strainer, replace strainer.

GO TO NEXT PAGE

2-42

|