|

| |

TM 55-2915-335-30&P

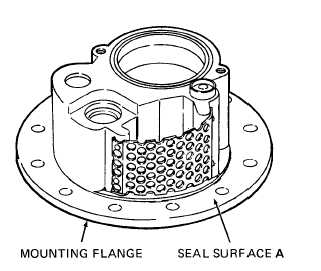

2-15. PUMP HOUSING/ MOUNTING FLANGE - lNSPECT/REPAIR (Cont)

2-15

b.

c.

Do not use glass or metal tools to scrape

dirt or locking compound from pump

housing surfaces. Scraping with metal or

glass will destroy the thin, protective coat-

ing on the housing. This could lead to

leaks or early failure of the pump.

Remove all residue from mounting flange seal sur-

face A. Use plastic scraper, if needed, to scrape

away residue. Do not use glass or metal scrapers

on seal surfaces. Scraping with metal or glass will

destroy the thin, protective coating on housing.

Make sure all preformed packing grooves are

clean. If necessary use a wooden or plastic scraper

to clean grooves.

2. INSPECTION AND REPAIR OF HOUSING

a.

b.

NOTE

Inspection of the pump housing in this task is limited to the mount-

ing flange and cartridge bore. Also covered is the inspection of the

inlet screen. For inspection of all other items refer to the individual

tasks.

Visually inspect all surfaces of pump housing for cracks. If any cracks are found, replace pump housing mount-

ing flange.

Visually inspect mounting flange seal surface A for scratches, nicks, or burrs. Run your finger lightly over any

defects; if sharp edges are felt they must be removed. Polish off sharp edges of scratches, nicks, and burrs using

500 or 600 grit, wet or dry, emery paper. Moisten emery paper with water.

GO TO NEXT PAGE

2-41

|