|

| |

TM 55-2915-335-30&P

2-11. PUMP CANISTER - lNSPECT/REPLACE (Cont)

2-11

3. INSPECTION

a.

b.

c.

d.

e.

f.

Run your finger along the packing groove in the

pump housing. Feel for any scratches or sharp

edges that may damage preformed packing.

Remove sharp edges of nicks or scratches using a

500 or 600 grit, wet or dry, emery paper. After

sanding, clean surface with solvent.

If edge of packing groove is broken off replace

pump housing per the instructions and illustra-

tions in paragraph 2-15.

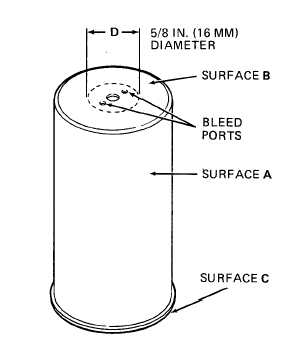

Visually inspect canister wall (surface A) and top

(surface B) for dents. If there is any dentin sur-

face, discard canister.

Place canister with flange down, on a flat surface.

Check for any twisting, warping or damage that

would prevent flange seating flush on surface. If

any portion of flange surface C is raised from flat

surface, discard canister.

Inspect umbrella seating surface, area D, for nicks

or scratches. If nick or scratches cannot be com-

pletely removed by polishing with 500 or 600 grit,

wet or dry emery paper, replace canister. When

polishing sealing surface, moisten emery paper

with water. Wipe surface clean with solvent.

Inspect canister bleed ports for blockage. Remove

any blockage using a wooden toothpick, or similar

object.

GO TO NEXT PAGE

2-27

|