|

| |

TM 55-2915-335-30&P

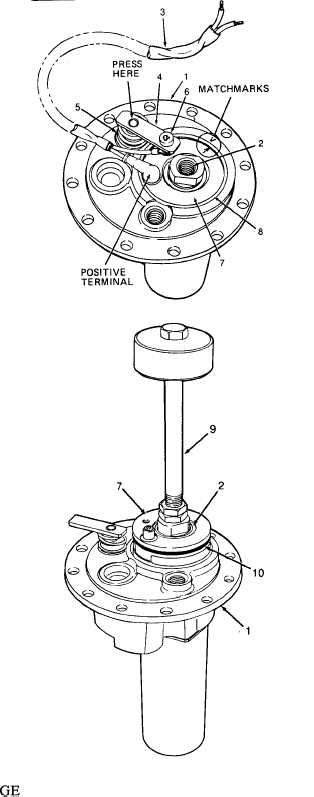

2-10. PUMP AND HOUSING ASSEMBLY - lNSPECT/REPLACE/REPAIR (Cont)

2-10

b. Drain any excess fuel and solvent from drain

port (2).

c. Blow-dry outer surfaces of pump with compressed

air, 30 psi (207 KPa) maximum.

2. REMOVAL

a. If cable assembly (3) is attached, lift rubber in-

sulator boot from positive terminal. Unscrew con-

nector from positive terminal.

Apply pressure directly over valve spring

when opening or closing valve stem as-

sembly. Trying to compress valve spring

from free end of valve arm will cause

b.

c.

d.

e.

f.

valve arm to bend. When removing or in-

stalling shoulder screw, keep valve arm

depressed.

Place thumb on valve stem assembly (4), above

spring (5). Press valve stem assembly (4) in toward

pump housing.

Unscrew shoulder screw (6). Remove cable as-

sembly (3). Rotate valve stem assembly (4) away

from cartridge (7).

Using a small screwdriver, pry end of retaining

ring (8) from seat in pump housing (1). Place

screwdriver tip between retaining ring and pump

housing. Rotate pump housing counterclockwise

to remove retaining ring.

Screw cartridge pulling tool (9) (Appendix D) into

drain port (2). Slide hammer of pulling tool (9)

against bolt head to remove cartridge (7) from

fuel boost pump (1). Unscrew pulling tool from

cartridge.

Use a wooden or plastic probe to remove pack-

ings. Do not use a screwdriver or other sharp me-

tal tool. Remove three preformed packings (10)

from pump cartridge (7). Discard packings; they

cannot be reused.

GO TO NEXT PAGE

2-22

|