|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. MOTOR FAILS TO START, LOW OR NO CURRENT DRAW (Cont)

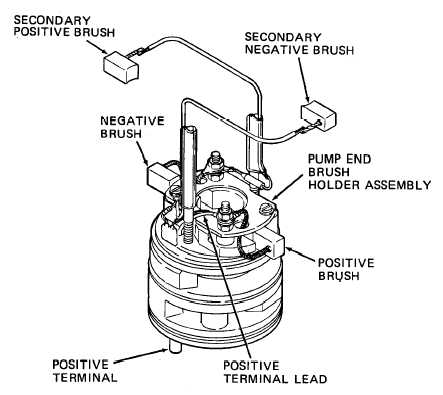

Step 3. Check lower brush holder wiring: Remove armature and field tube assembly (paragraph 2-18) to

expose lower brush holder. Compare motor wiring with illustration. Check terminals on pump-end brush

holder for a loose or broken connection. If electrical leads are good and no connections are loose or

broken, proceed to Step 4.

If electrical wiring is bad or connections are loose or broken, repair wiring. Inspect and re-

place wiring and connectors per the instructions and illustrations in paragraph 2-23.

Step 4. Check condition of brushes. Check for shunt lead caught on spring. Inspect brush contact surface

for wear and defects (paragraph 2-20). Check for brush springs out of place. Check both ends of springs. If

brushes, springs and shunt leads are good, proceed to Step 5.

Inspect and replace worn, chipped, or cracked brushes per the instructions and illustrations

in paragraphs 2-20 and 2-23.

Step 5. If brush connections and circuits are good, armature is defective.

Inspect armature per instructions and illustrations in paragraph 2-18. Replace if defective.

2-8

|