|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. MOTOR FAILS TO START, LOW OR

NO CURRENT DRAW

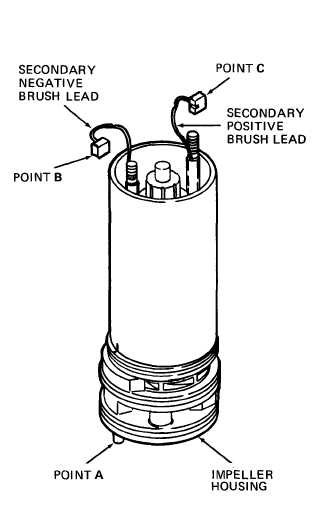

Step 1. Check brush circuit: Remove pump

cartridge from housing (paragraph 2-10). Iso-

late brush circuit by removing cover-end

brushes from brush holder (paragraph 2-17).

Use a multimeter to check for continuity be-

tween positive terminal, point A, and secon-

dary positive brush, point C. If you have con-

tinuity, circuit is good; proceed to Step 2.

NOTE

Secondary positive brush lead is

secured to motor stud on opposite

side from positive terminal, point A.

If circuit is open, a solder joint

between leads is probably open.

Inspect and repair per instruc-

tions and illustrations in

paragraph 2-23.

Step 2. Check circuit to secondary negative

brush lead. Use multimeter to check for con-

tinuity between negative secondary brush,

point B, and any point on the impeller housing.

If you have continuity, circuit is good; proceed

to Step 3.

If circuit is open, secondary

lead to ground is broken. In-

spect and repair per instruc-

tions and illustrations in

paragraph 2-23.

2-7

|