|

| |

TM 55-2915-335-30&P

Table 2-1. Fault Isolation - Continued

From block 13

l

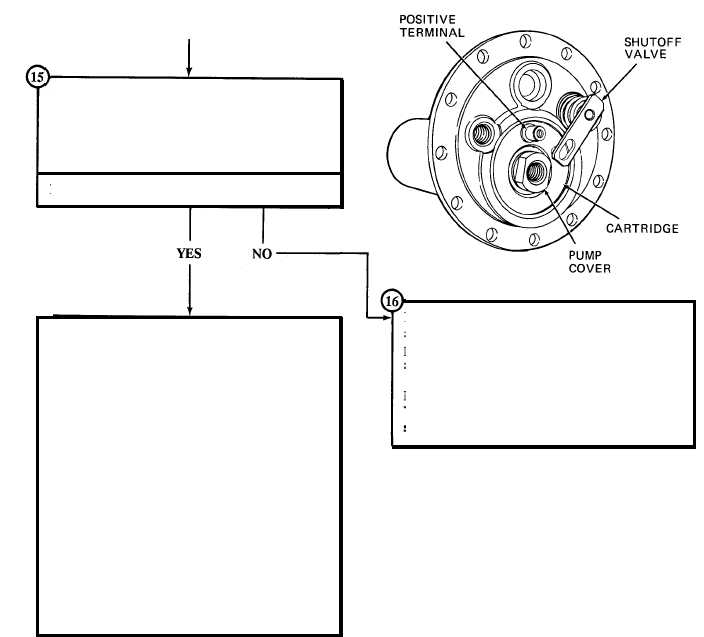

Check pump or cartridge for leaks.

l

Wipe face of pump assembly dry.

l

Turn pump ON.

l

Check pump face for solvent leaking from

pump.

Does pump face stay dry?

NOTE

Perform the following check only if the complete

pump assembly (housing and cartridge) is being

serviced.

l

Inspect vapor bleed valve and fuel bleed valve

for blockage.

l

Drain calibration fluid from test tank and

pump.

l

Remove pump assembly from test tank.

l

Wipe pump surfaces dry.

l

Inspect vapor bleed valve for blockage per

instructions and illustrations in paragraph

2-12.

l

Inspect canister fuel bleed valve for

blockage per instructions and illustrations

in paragraph 2-11.

Dry wet surfaces, and repeat checks to isolate

source of leak. Check parting surfaces around

positive terminal, pump cover, cartridge, and

shutoff valve.

Proceed to Malfunction Number 8 of Table 2-2.

When source of leak has been located, follow in-

structions in troubleshooting step that applies.

2-6

|