|

| |

TM 55-2915-335-30&P

2-24. IMPELLER HOUSING - lNSPECT/REPLACE (Cont)

2-24

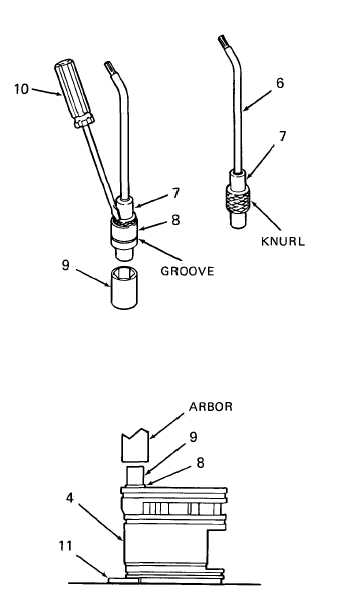

4. REPLACE POSITIVE TERMINAL

a. Cut a 4-inch (100 mm) length of lead wire (6)

(Item 3, Appendix B, Bulk Items List). Strip in-

sulation back about 1/4 inch (6 mm) at one end.

Tin bare end with solder (Item 8, Appendix C).

b. Install tinned end of wire (6) in terminal pin (7),

as shown. Heat terminal with soldering iron to

bond lead wire to terminal. Check for good bond

by tugging on lead wire.

c. Apply one drop of locking compound (Item 5,

Appendix C) to knurl of terminal pin (7). Place

terminal pin (7) in terminal housing (8). Place

terminal housing (8) into a 5/16 inch socket (9) or

equivalent. Press terminal pin (7) into terminal

housing (8) using a small screw driver (10). Ter-

minal pin (7) is fully inserted into terminal hous-

ing when end of pin protrudes through housing.

d. TI INSPECT. Inspect solder joint to make sure it

is secure. Check that terminal pin is fully posi-

tioned in terminal housing.

e. Insert primary lead wire (6) into terminal bore in

impeller housing (4) and through wire port in im-

peller housing. Place impeller housing on hand

operated arbor press, as shown. Make sure area

under primary terminal bore is supported. It may

be necessary to place a flat metal washer (11) be-

tween impeller housing and arbor plate to support

the outer edge below the terminal.

GO TO NEXT PAGE

2-91

|