|

| |

TM 55-2915-335-30&P

2-24. IMPELLER HOUSING - lNSPECT/REPLACE (Cont)

2-24

5.

f.

When pressing terminal housing into impeller housing bore, use only

enough pressure to seat terminal housing into bore. Excessive pres-

sure will smash nylon terminal housing.

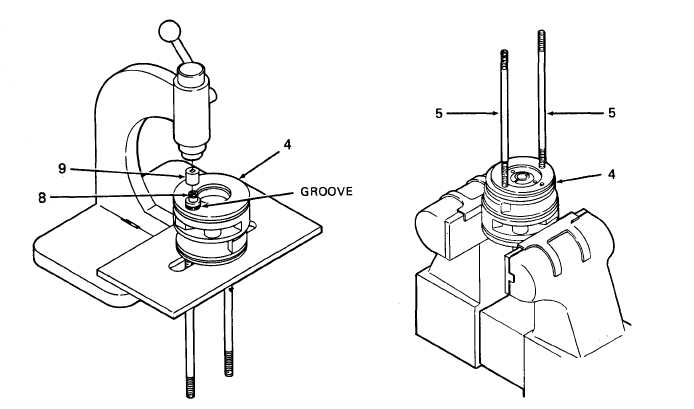

Apply one drop of locking compound (Item 5, Appendix C) to groove in terminal housing (8). Lineup terminal

assembly with bore. Slowly press terminal assembly into impeller housing bore until fully seated. Use a 5/16 inch

socket (9), or equivalent, as a driver tool between terminal housing (8) and arbor. This will prevent arbor from

pressing terminal pin (7) end back into terminal housing.

REPLACE MOUNTING STUD

a. Apply one drop of thread locking compound (Item 4, Appendix C) to leading threads of stud (5).

b. Screw stud into impeller housing (4). Measure stud height above housing. Adjust stud height to between 4.073

and 4.113 inches (between 103,45 and 104,47 mm).

NOTE

FOLLOW-ON MAINTENANCE Install positive and negative

secondary electrical circuits (paragraph 2-23).

END OF TASK

2-92

|