|

| |

TM 55-2915-335-30&P

2-24. IMPELLER HOUSING - lNSPECT/REPLACE (Cont)

2-24

3. INSPECTION

a.

b.

c.

d.

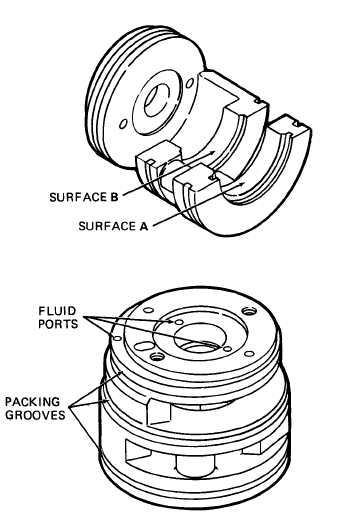

Run your finger along the packing grooves in the

impeller housing. Feel for any sharp edges, nicks,

or scratches that may damage preformed packings.

Remove sharp edges, nicks, or scratches, using 500

or 600 grit, wet or dry emery paper. After sanding,

clean surface with a cloth moistened with dry

cleaning solvent.

If edge of packing groove is broken off, replace

impeller housing.

Using a flashlight, visually inspect pump cover and

inlet seal packing seats, surfaces A and B, for

nicks, burrs, or scratches. If a defect is found on

either sealing surface,

it must be completely

removed flush with the surrounding surface as

follows:

(1)

(2)

(3)

Use 500 or 600 grit, wet or dry emery paper

moistened with water. Polish the bore

diameter until the sharp edges and the entire

raised portion of defect is removed.

Lightly run your finger along the entire bore

area of surfaces A and B and make sure you

do not feel any defects. After you are

satisfied with the finish, use a clean cloth

moistened in cleaning solvent to clean the in-

side of the bore.

Use a flashlight to check the reflected surface

to make sure the raised portion of the defect

is removed.

Check each of the three fluid ports on motor end

of housing for blockage. Clear any blockage found

with wire probe, 0.035 inch (0,89 mm) diameter

maximum. If fluid port blockage cannot be

removed, replace impeller housing.

GO TO NEXT PAGE

2-90

|