|

| |

TM 55-2915-335-30&P

2-24. IMPELLER HOUSING - lNSPECT/REPLACE (Cont)

2-24

2. CLEANING

Compressed air aimed at the skin can

cause serious injury or death. Wear

goggles and never use over 30 psi (207

kPa) of compressed air for cleaning.

Cleaning solvent can be hazardous to

your health. Use solvent only in well-

ventilated areas. Avoid breathing solvent

vapors. Do not use solvent near an open

flame or other source of high heat. Al-

ways wear gloves, apron, and goggles

when using cleaning solvent. Store solvent

in approved metal container only.

Do not use metal or glass tools to scrape dirt or locking compound

from impeller housing surfaces. Scraping with metal or glass will

destroy the thin, protective coating on the housing. This could lead

to leaks or early failure of the pump.

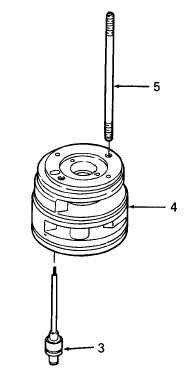

a. Clean Housing. Wash impeller housing (4) with non-woven cloth (Item 1, Appendix C) and dry cleaning sol-

vent (Item 7, Appendix C). Clean debris from all exposed surfaces. Use soft-bristled brush to scrub packing

grooves. If needed, use plastic or wood scraping tool to scrape away hardened deposits. Do not use metal or

glass scraping tools to clean housing surfaces.

b. Clean Positive Terminal Bore. Locking compound was used to seal positive terminal assembly (3) in housing

(4). Use a plastic or wooden tool to scrape residue from bore.

c. Clean Threaded Holes. If replacing stud (5), use #10-32 tap to clean threads in housing (4). Run tap in and

out of threads two or three times to remove all locking compound residue.

d. Rinse impeller housing (4) in solvent (Item 7, Appendix C). Wipe down all surfaces with cleaning cloth (Item 1,

Appendix C). Be sure to drain solvent from primary lead wire port. Blow-dry all ports and surfaces with

compressed air, 30 psi (207 kPa) maximum.

GO TO NEXT PAGE

2-89

|