|

| |

TM 55-2915-335-30&P

2-23. ELECTRICAL CIRCUITS - lNSPECT/REPLACE (Cont)

2-23

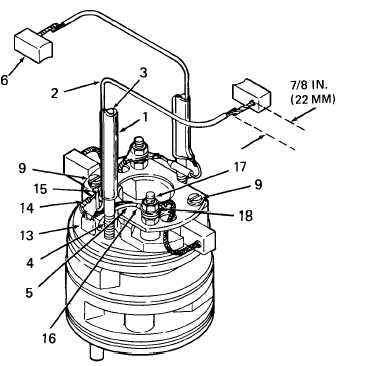

(6) Cut off lead wire (2) even with top of stud (3). Strip 1/4 inch (6,4 mm) of insulation from wire end. Cut

shunt lead of new brush (6) to about 7/8 inch (22 mm). Tin ends of shunt lead and lead wire. Overlap

leads 1/4 inch (6,4 mm) and solder. Use rosin-core solder (Item 8, Appendix C).

(7) Install 3/4 inch (19 mm) length of shrink tube over long lead of capacitor (13). Use 0.062-inch diameter

shrink tube (Item 4, Appendix B, Bulk Items List). Use heat gun to shrink tubing to lead wire.

(8)

Route primary lug terminal (5) and long

capacitor lead between mounting stud (3)

and brush holder (8). Both leads must pass

below brush lead (2). Place new terminal (16)

on stud (17). Place positive lead wire (5)

along side terminal (16). Cut positive lead to

reach the terminal with minimum slack in

lead wire.

(9) Strip positive lead end 1/4 inch (6,4 mm).

Crimp positive lead wire (5) and capacitor

lead (13) lead together in terminal lug (16).

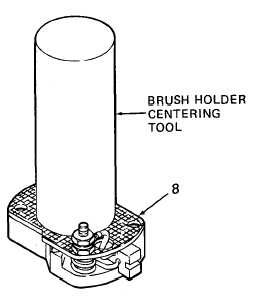

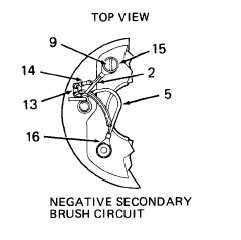

d. Loosen screws (9). Install terminal lug (15) under

screw (9) as shown in top view. Make sure washers

are in place under screws. Install brush holder cen-

tering tool (Figure 1, Appendix D) in center of

brush holder assembly (8). Carefully insert nipple

of centering tool in pump end bearing. Tighten

screws (9). Remove centering tool.

GO TO NEXT PAGE

2-85

|