|

| |

TM 5-4320-305-24

2-18. REPLACE/REPAIR SUCTION ASSEMBLY, STRAINER ASSEMBLY,

AND GATE VALVE (Continued)

INSTALLATION:

WARNING

Death or serious injury could occur if unauthorized or un-

necessary personnel are in the hoisting area. Permit only per-

sonnel actually engaged in the hoisting operation to be near the

unit and hoisting equipment. All instructions for the hoisting

operations must come from one authorized person. Injury to

personnel or damage to equipment could occur from improper

hoisting. Hoist the load slowly to avoid tearing out lifting bail

assembly, slipping slings, or load shift. Do not jerk the load or

swing it from side-to-side when hoisting. This places additional

stress on hoisting components which can cause failure and loss of

load. Be sure hoisting equipment is on solid footing and is

suitable for the size of the load. Watch boom angle and overhead

clearance when hoisting.

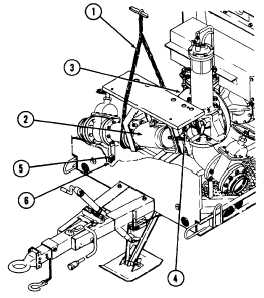

1 Position a suitable lifting device (1) equipped with a

spreader bar and slings over suction assembly (2).

2 Attach slings around assembly and put tension on

slings. Make sure assembly is properly supported.

Spread slings on spreader bar so that slings hang

vertically when attached to assembly.

3 Lift suction assembly (2) and remove from blocks on

work platform. Lower carefully so that suction

assembly (2) alines with pump body (3). Aline holes

in strainer body with studs on pump body. When

these holes and studs are alined, slide suction

assembly (2) toward pump body (3) so that flanges

mate and engage properly.

4 Install nuts and lockwashers (4) on pump body studs.

Do not tighten hex nuts.

5 Install bolts (5) and nuts and lockwashers (6) on trailer

frame. Do not tighten bolts.

6 Tighten nuts (4) alternately until secure. Tighten bolts

(5) securely in a cross pattern.

2-75

|