|

| |

TM 5-4320-305-24

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

4

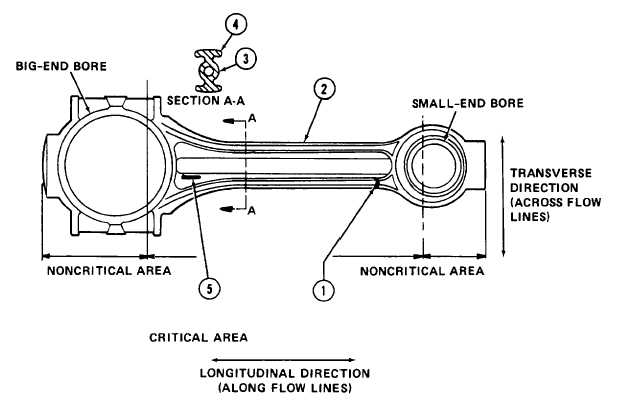

Repair minor cracking in the transverse direction (1) (across flow lines) of the connecting rod (2) as long as the

cracks are no longer than 0.50 inch (12.70 mm) and can be completely removed by grinding no deeper than 0.0156

inch (0.3962 mm). If the cracking extends over the edge of the H section (3) or on both sides of the connecting rod

flange (4), the crack must be completely removable, by grinding no deeper than 0.0050 inch (0.1270 mm).

Otherwise, replace connecting rod (2) in either case. Minor cracking in the longitudinal direction (5) (along flow

lines) may be removed by grinding no deeper than 0.0313 inch (0.7950 mm). If crack is deeper, replace

connecting rod. Remove rust. Do not finish connecting rod.

NOTE

When grinding out minor nicks, abrasions, or cracks on connecting rod, make

sure ground areas form smooth contours with adjacent ungrounded areas.

5

Repair bearing shells.

a.

Replace bearing shells if they are excessively worn, out-of-tolerance, out-of-round, or show any scoring,

pitting, flaking, etching, or signs of overheating. Replace bearing shells if they show any bright spots on the

back or outside surfaces.

b.

Install new bearing shells in connecting rod only if necessary. Follow procedure described in step 13. Tighten

and retighten big-end bolts in accordance with procedure described in step 9.

4-90

|