|

| |

TM 5-4320-305-24

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

c.

If the side clearance is greater than 0.0315 inch (0.8 mm), either the connecting rod or crankpin fillets (9) on

the crankshaft (10) are worn. Recheck and remeasure connecting rod. Replace connecting rod if width is

below tolerance limits. If not, recheck crankpin width (8) on crankshaft (10). Crankpin width should be 1.4173

to 1.4189 inches (36.0 to 36.04 mm). If crankpin width is greater than 1.4189 inches (36.04 mm), replace

crankshaft. Connecting rods and big-end support bearings may also have to be replaced.

REPAIR:

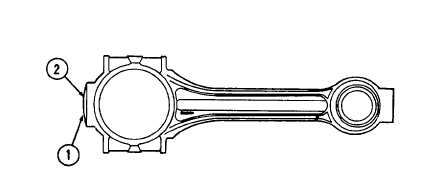

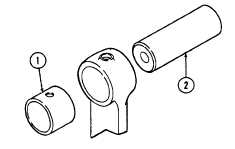

1

Replace small-end bushing (1) if scored, overheated, out-of-round,

or damaged. Replace if inside diameter (pressed in) or outside

diameter is beyond the tolerance limits. Replace bushing if piston

pin (2) (new or acceptable) clearance is outside the tolerance

limits.

2

Replace piston pin (2) if clearance in new or acceptable small-end

bushing is outside the tolerance limits.

3

Replace connecting rod if bent, warped, cracked, or damaged. Replace if bore for small-end bushing is outside

tolerance limits. Replace if bearing shell bore or side clearance is outside tolerance limits. When replacing

connecting rods, make sure color code (1) on bottom of bearing cap (2) is the same as the replaced rod, indicating

the same weight class. The connecting rods within any weight class should not differ more than 1.058 ounce (30

grams).

4-89

|