|

| |

TM 5-4320-305-24

4-11. REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

c.

Remeasure bearing shell bore in accordance with step 14. The bearing shell bore, for example, should be

2.5209 to 2.5224 inches (64.03 to 64.069 mm). However, if the bore measures an additional 0.0008 inch

(0.020 mm) on either side of tolerance limits, the connecting rod and bearing shells would still be acceptable

for reinstallation. The tolerance limits would then become 2.5217 to 2.5232 inches (64.05 to 64.089 mm) and

the connecting rod and bearing shells would be acceptable for further use.

d.

If bearing shell bore measurements are still outside the extended tolerance limits, the connecting rod must be

replaced. This would include replacement of small-end bushing, bearing shells, bearing cap, dowel pin, and

big-end bolts.

INSTALLATION:

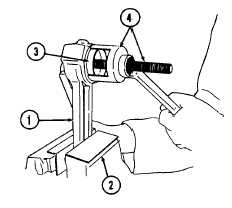

1

If connecting rod (1) has been replaced, clamp new

connecting rod into padded vise (2) and pull in small-end

bushing (3) with piston pin bush inserter No. 131310 (4).

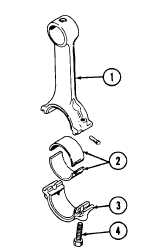

2

If connecting rod (1) and/or bearing shells (2) have been replaced,

matchmark connecting rod, bearing shells, and bearing cap (3) for

each cylinder. Always use new big-end bolts (4) for installation of

connecting rod and bearing shells onto crankpin on crankshaft.

Tighten bolts (2) to 22.13 ft-lb (30 N.m) torque. Using a torque

gage, retighten bolts an additional 60 degrees, then an additional

30 degrees.

4-91

|