|

|||

|

|

|||

|

Page Title:

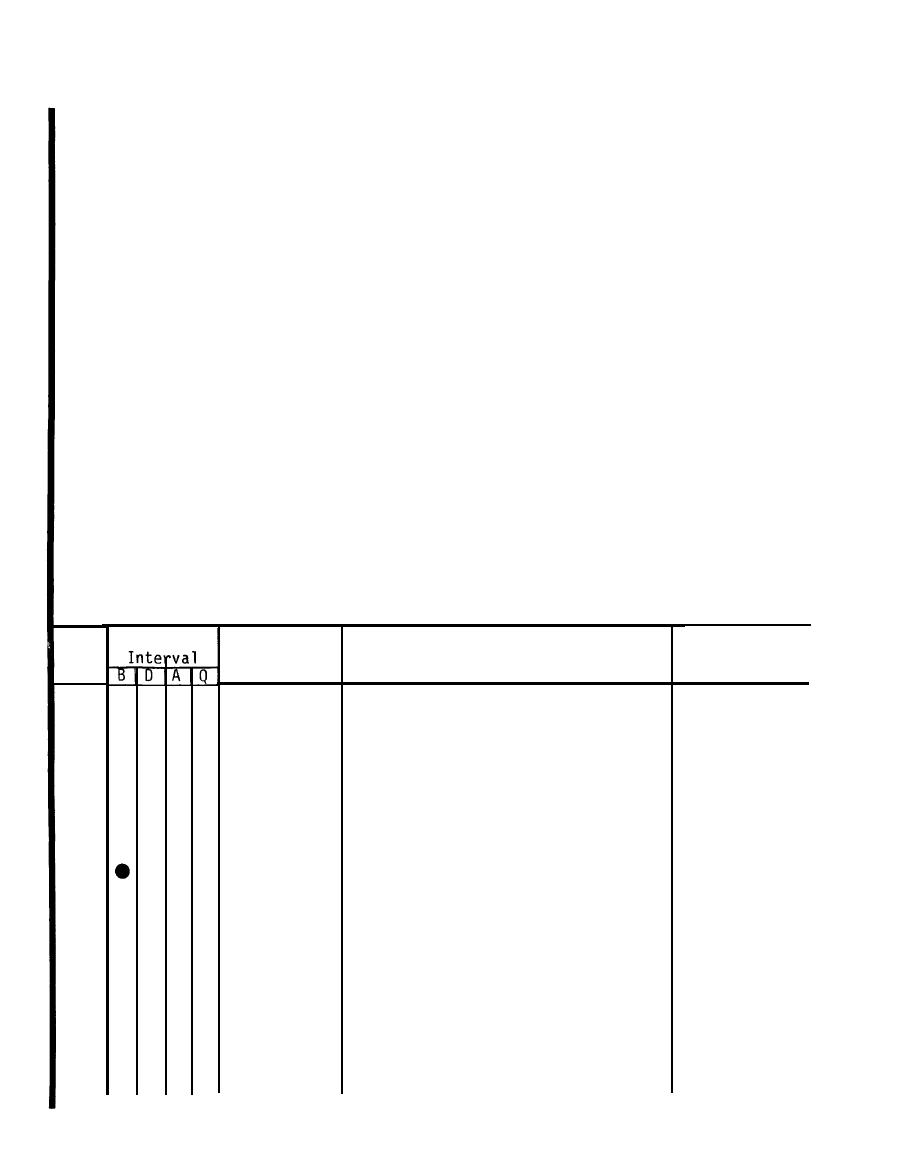

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 5-4320-273-14

c. Leakage definitions for operator/crew PMCS shall be classified as follows:

Seepage offluid (as indicated by wetness ordiscoloration) not great enough

Class I

to form drops.

Leakage of fluid great enough to form drops but not enough to cause drops

Class II

to drip from item being checked/inspected.

Leakage of fluid great enough to form drops that fall from the item being

Class Ill

checked/inspected.

CAUTION

Equipment operation is allowable with minor leakages (Class I or II). Of course, you

must consider the fluid capacity in the item/system being checked/inspected. When

in doubt, notify your supervisor.

When operating with Class I or Class II leaks, continue to check fluid levels as required

in your PMCS.

Class Ill leaks should be reported to your supervisor or organizational maintenance.

Operator/Crew Preventive Maintenance Checks and Services

NOTE

Within designated interval, these checks are to

be performed in the order listed.

D-During

Q-Quarterly

A-After

B-Before

Equipment is

Procedures

Item to be

Not Ready/

Check for and have repaired

Item

Inspected

Available if:

No.

or adjusted as necessary

NOTE

Perform lubrication prior to

or in conjunction with before

PMCS . Refer to LO 5-4320-273-

12. Keep the pumping

assembly free of dirt and oil

on all external surfaces.

Pumping

Make the following walk around

1

Assembly

checks:

Class III oil

a. Check for leaks (oil or fuel)

on, around, or under pumping

leak or any

fuel leakage

assembly.

is found.

b. Check for loose, missing, or

Fire

damaged parts or equipment such as

extinguisher,

the fire extinguisher, ground rod,

ground rod,

or shrouding. Check tires for

or shrouding

missing.

inflation.

Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |