|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Cleaning and Inspection.

(5) Inspect the female disc (11) and male disc

(1) Discard and replace the valve packing set

(12) for cracks and for scoring of the seating area.

(6, fig. 4-18) and the gasket (10).

Replace damaged parts.

WARNING

(6) Replace all parts damaged beyond repair.

Clean all parts in a well-ventilated area.

c. Reassembly and Installation.

Avoid inhalation of solvent fumes and

(1) Reassemble the gate valve in the reverse

prolonged exposure of the skin to

order of disassembly. Refer to figure 4-18.

cleaning solvent. Wash exposed skin

(2) Install the gate valve according to either

thoroughly.

figure 4-16 or 4-17.

(2) Clean all remaining parts with cleaning

(3) After reassembly and installation, start the

solvent (fed. spec. P-D-680); dry thoroughly with

centrifugal pump and check for leaks. Correct any

compressed air.

leaks before you restore the pumping assembly to

(3) Inspect the valve bonnet (9) and body

service.

(15) fox cracks, damaged threads and flanges.

Inspect the stem threads of the bonnet for wear and

a. Adjustment. You can adjust the check valve

damage. Inspect the seat rings in the body. You can

for manual or automatic closing as follows:

repair minor damage to seat rings with a fine emery

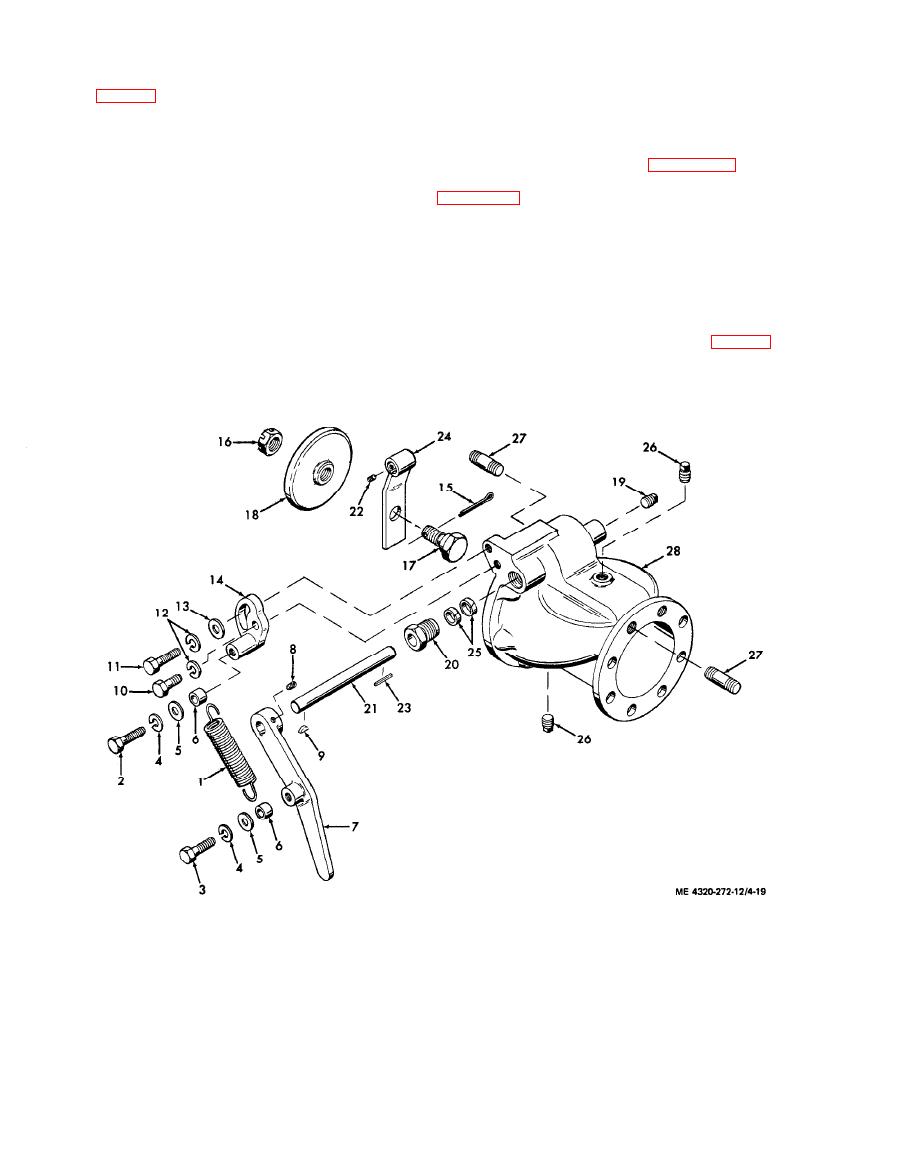

(1) Loosen cap screws (10 and 11, fig. 4-19)

cloth. You must remove stock evenly to prevent

to permit spring bracket (14) adjustment.

leaking.

(4) Inspect the disc stem (13) and valve stem

(14) for distortion and damaged threads.

15. Cotter pin

22. Setscrew

8.Setscrew

1. Spring

23. Key

16. Nut

2. Cap screw

9. Key

24. Valve arm

10. Cap screw

17. Shoulder bolt

3. Cap screw

11. Cap screw

25. Packing ring

18. Valve disc

4. Lock washer

26. Pipe plug

12. Lock washer

19. Pipe plug

5. Flat washer

27. Stud

13. Flat washer

20. Packing nut

6. Spacer

28. Body

14. Spring bracket

21. Shaft

7. Handle

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |