|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

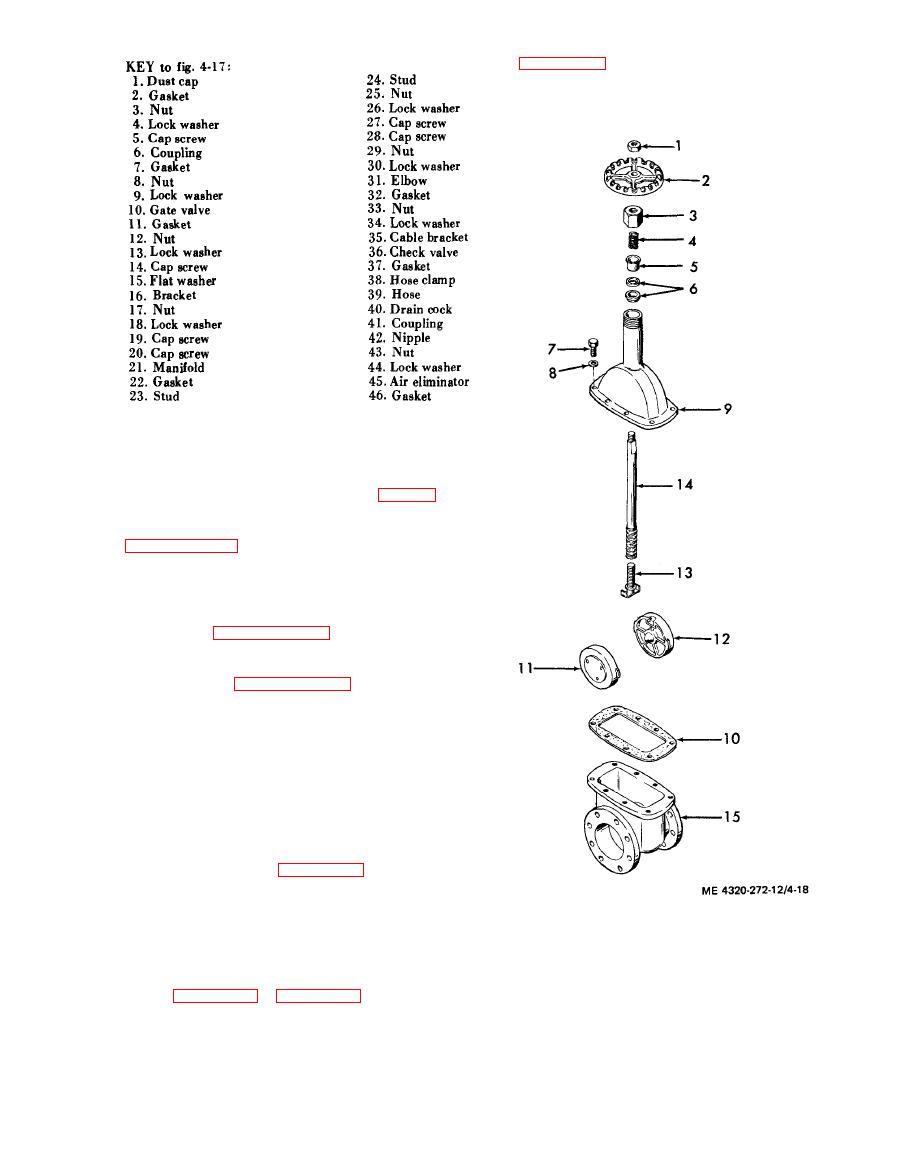

in figure 4-18. You should not attempt to remove

the seat rings from the valve body.

b. Cleaning and Inspection.

(1) Discard and replace all gaskets. Clean all

remaining parts with cleaning solvent (fed. spec. P-

D-680); dry thoroughly.

(2) Inspect the gate valve (10, fig. 4-17) for

cracks and damaged flanges. Operate the valve

handwheel to check for free operation. Refer to

(3) Inspect the check valve (36) for cracks,

loose studs, and other apparent damage. Check the

lever for free operation. If the check valve operates

improperly or is damaged, you can repair valve as

described in paragraph 4-44.

(4) Inspect the air eliminator assembly (45)

for cracks and other damage. If damaged, repair it

as described in paragraph 4-45.

(5) Inspect all other piping parts for cracks

and for damaged flanges. Inspect the discharge

manifold (21) for damaged studs (23 and 24).

Replace as necessary. If stud mounting holes in the

manifold are damaged, replace the entire manifold.

(6) Replace all defective parts,

(7) Touch up or repaint all areas requiring it.

c. Reassembly and Installation.

(1) Using all new gaskets, reassemble the

discharge piping in the reverse order of

disassembly; refer to figure 4-17.

(2) After you reassemble the piping, start and

operate the centrifugal pump and check for leaks.

Correct any deficiencies.

1. Nut

9. Bonnet

4-43. Gate Valve

2. Handwheel

10. Gakset

a. Removal and Disassembly.

3. Packing nut

11. Female disc

4. Spring

12. Male disc

(1) Remove the gate valve as indicated in

5. Retainer

13. Disc stem

either figure 4-16 or figure 4-17.

14. Valve stem

6. Packing set

(2) Disassemble the gate valve following the

7. Cap screw

15. Body

sequence of the index numbers in the exploded view

8. Lock washer

view.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |