|

|||

|

|

|||

|

Page Title:

Maintenance of Electrical System |

|

||

| ||||||||||

|

|

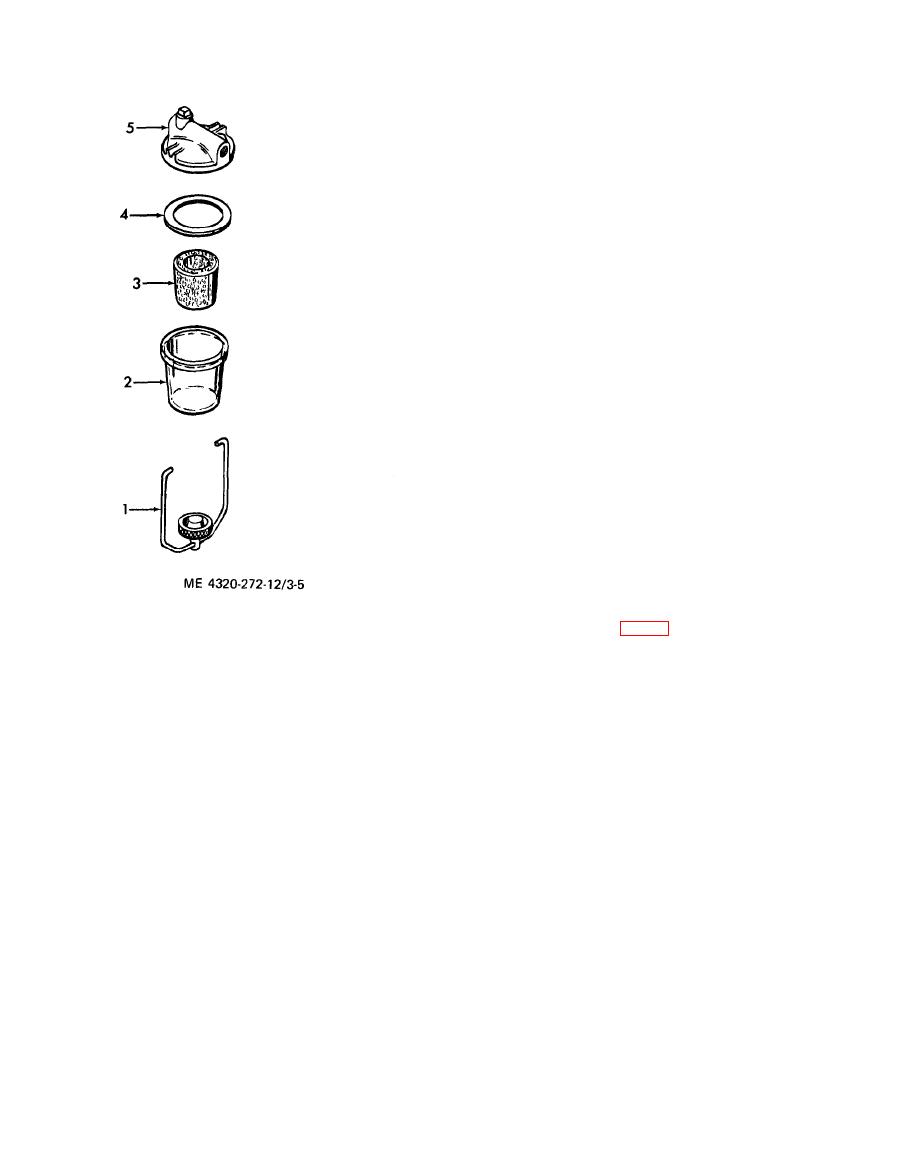

(3) If the strainer element (3) is con-

taminated, replace it with a new one.

(4) Position the gasket (4) and fuel bowl (2)

on the fuel strainer housing (5). Swing the bail (1)

into position and tighten the bail nut to hold the

bowl in place.

(5) After you h a v e reinstalled the fuel

strainer, open the fuel selector valve and check for

leaks. Correct any leaks.

Operator/crew maintenance of the electrical

system consists primarily of servicing the battery.

Keep battery filled to the required level with

distilled water. Keep the top of the battery and the

battery terminals clean. To protect the terminals

from corrosion, you can coat them with a light

application of vaseline or GAA lubricant.

Operator / crew maintenance of wheels consists

primarily of servicing the tires, as follows:

a. Clean tires and wheels with fresh, clean water.

b. Remove foreign material embedded in the

tires. If you remove nails or other penetrating

objects, be sure to inspect for puncture of the tube.

c. Inspect wheels and rims for damage. Inspect

tires for cracks, deep cuts, or separated tread.

d. Keep tires inflated to 60 psi.

e. R e p o r t

any defects or damage to

organizational maintenance personnel.

Service the suction strainer as follows:

1. Bail

4. Gakset

screw (1) and loosen the setscrew to release the

5. Fuel strainer housing

2. Fuel bowl

clamp (3). Now you can disengage the clamp from

3. Strainer element

the housing and remove the cover (4) and gasket

(5).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |