|

|||

|

|

|||

|

Page Title:

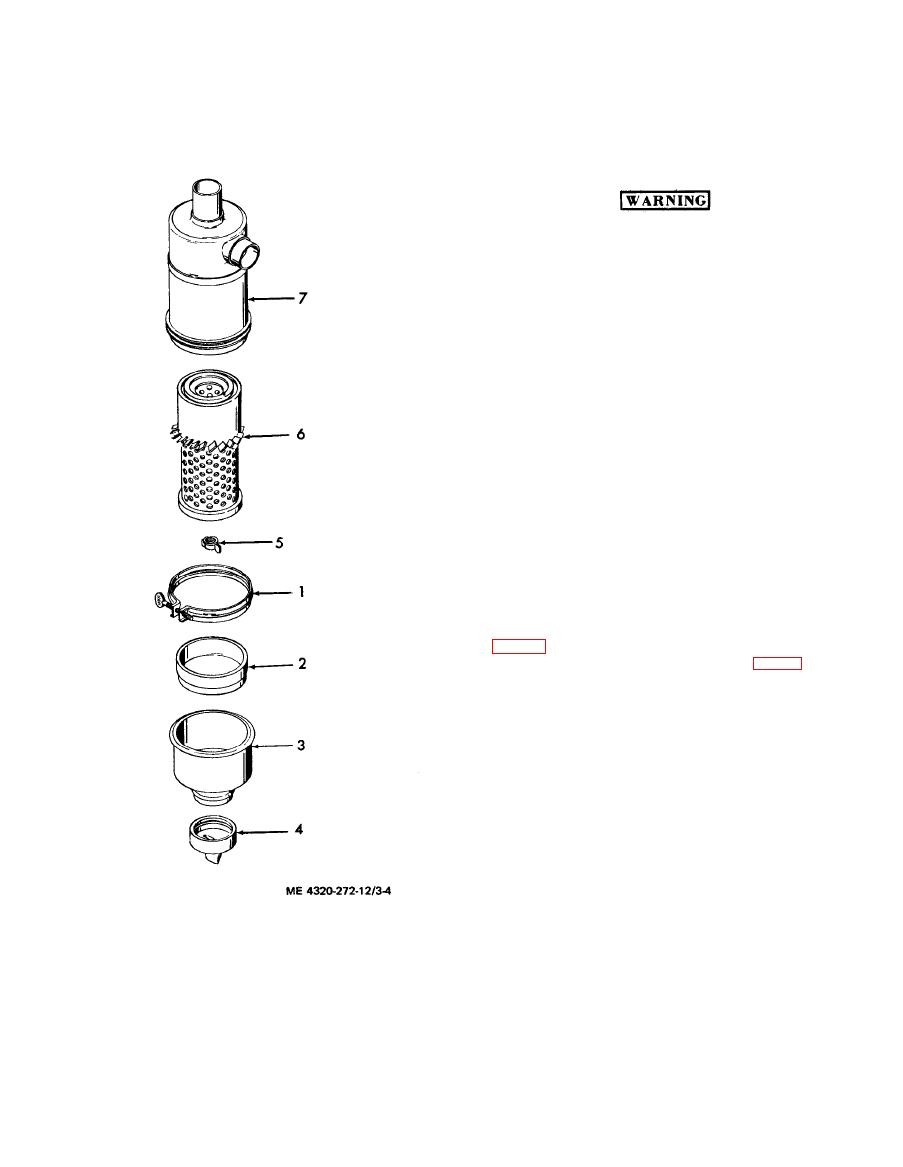

Figure 3-4. Air cleaner, exploded view. |

|

||

| ||||||||||

|

|

b. Servicing F u e l T a n k , L i n e s a n d F i t -

CAUTION

tings. Normal operation of the pump and engine

Do not attempt to clean the air cleaner

requires no maintenance of the fuel tank, lines, and

element with gasoline, kerosene, or

fittings other than that which is obvious such as

solvent.

filling tank with fuel and tightening loose fittings.

When engine operation becomes faulty or erratic,

y o u may need to perform one or all of the

following:

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of the skin to

cleaning solvent. Wash exposed skin

thoroughly.

( 1 ) Drain and clean fuel tank. To drain

contaminated fuel from tank, remove plug and

drain fuel into suitable container. Flush out the fuel

tank and fuel lines with solvent (fed. spec. P-D-

680 ). You can clean the strainer with a soft-bristled

brush to remove embedded material.

(2) Inspect the fuel tank and lines for leaks,

c r a c k s , dents, damaged threads, and broken

weldments. Report any damage to organizational

maintenance.

(3) Check for clogged fuel lines by loosening

slightly the fuel line nut at carburetor. If the line is

open, fuel will drip out at the loosened nut. If you

find that the fuel line is clogged, report it to

organizational maintenance.

c. Servicing Fuel Strainer. If you observe

moisture or other contaminants through the glass

bowl of the fuel strainer, service the strainer as

follows :

(1) Operate the fuel source selector valve (6,

fig. 2-2) to OFF.

(2) Loosen the nut on the bail (1, fig. 3-5) and

swing the bail aside to release the glass fuel bowl

(2). Empty the contents of the bowl and wipe it dry

with a clean cloth.

5. Wing nut assembly

1. Clamp assembly

6. Element

2. Baffle

7. Body

3. Dustcup

4. Vacuator valve

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |