|

|||

|

|

|||

|

Page Title:

Section VII. MAINTENANCE OF ENGINE LUBRICATING SYSTEM |

|

||

| ||||||||||

|

|

..

d. Reassemble the fuel strainer parts and tighten

b. Loosen bail nut (4) and swing the bail (5) to

the bail nut to secure the fuel bowl in place.

release the fuel bowl (2). Remove the fuel bowl and

e. Open the fuel shutoff cock (1) and check for

gasket. Empty the contents of the fuel bowl and

leaks. Correct any leaks.

wipe it clean with a lint-free cloth.

c. If necessary, remove the fuel filter element (3)

and clean it with an approved cleaning solvent.

Shake out excess solvent.

ENGINE

LUBRICATING

SYSTEM

Section VII.

MAINTENANCE

OF

3-12. General

engine oil pan is extremely important for long

engine life. If proper oil level is not maintained, the

parts of the engine will run dry, resulting in rapid

wear and premature failure of the engine.

b. The oil level is gaged with a dipstick which

indicates the amount of oil in the engine oil pan.

The engine uses a splash-type oil system in which a

projection on the bottom of the connecting rod

bearing cap dips into the oil with each revolution of

the crankshaft, splashing the oil around the interior

of the cylinder block to lubricate the crankshaft

bearings, connecting r o d b e a r i n g s , c a m s h a f t

bearings, governor parts, cylinder bore, and other

moving parts.

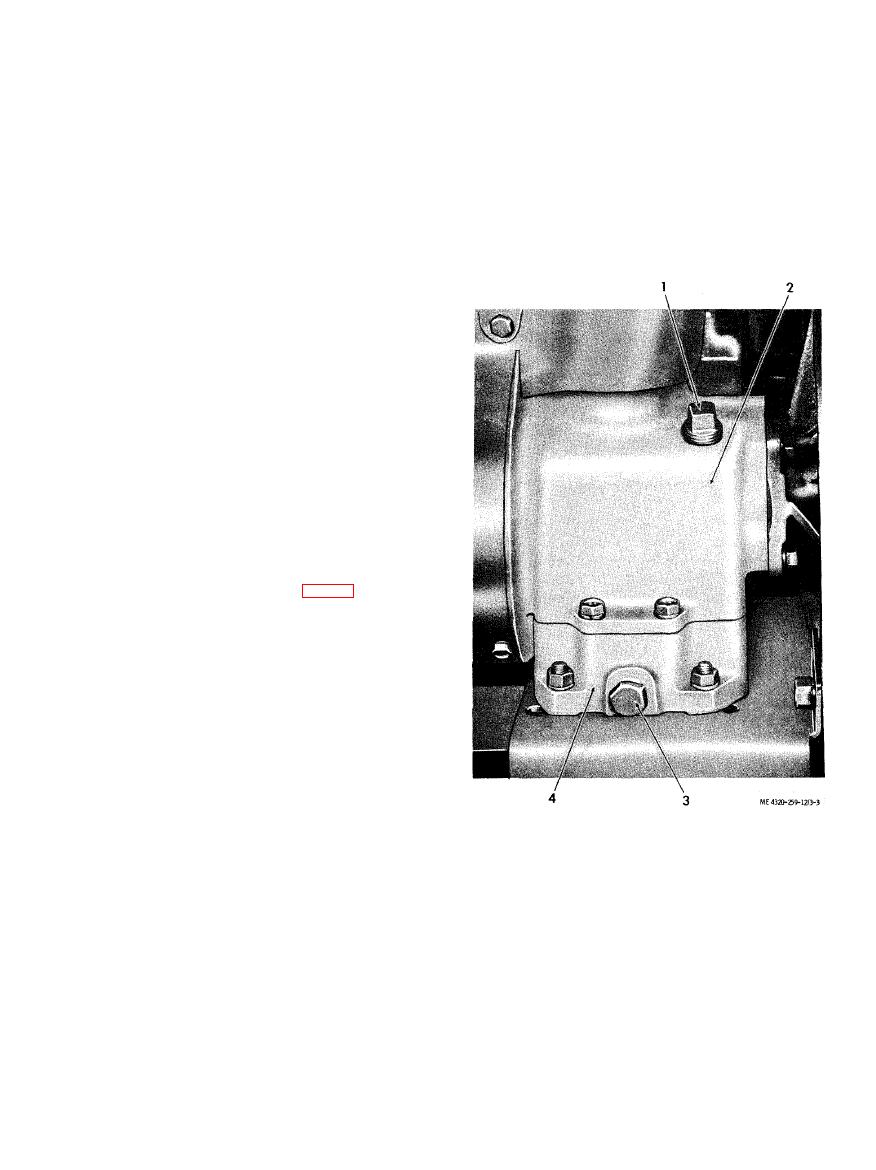

a. Daily, or at the start of each shift, check the

engine oil level as follows:

(1) Remove the dipstick (1, fig. 3-3) from the

crankcase (2) and check the oil level shown on it.

1. Dipstick

2. Crankcase

3. Drain plug

4. Oil pan

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |