|

|||

|

|

|||

|

Page Title:

SECTION III. GENERAL MAINTENANCE |

|

||

| ||||||||||

|

|

TM 5-4320-258-34

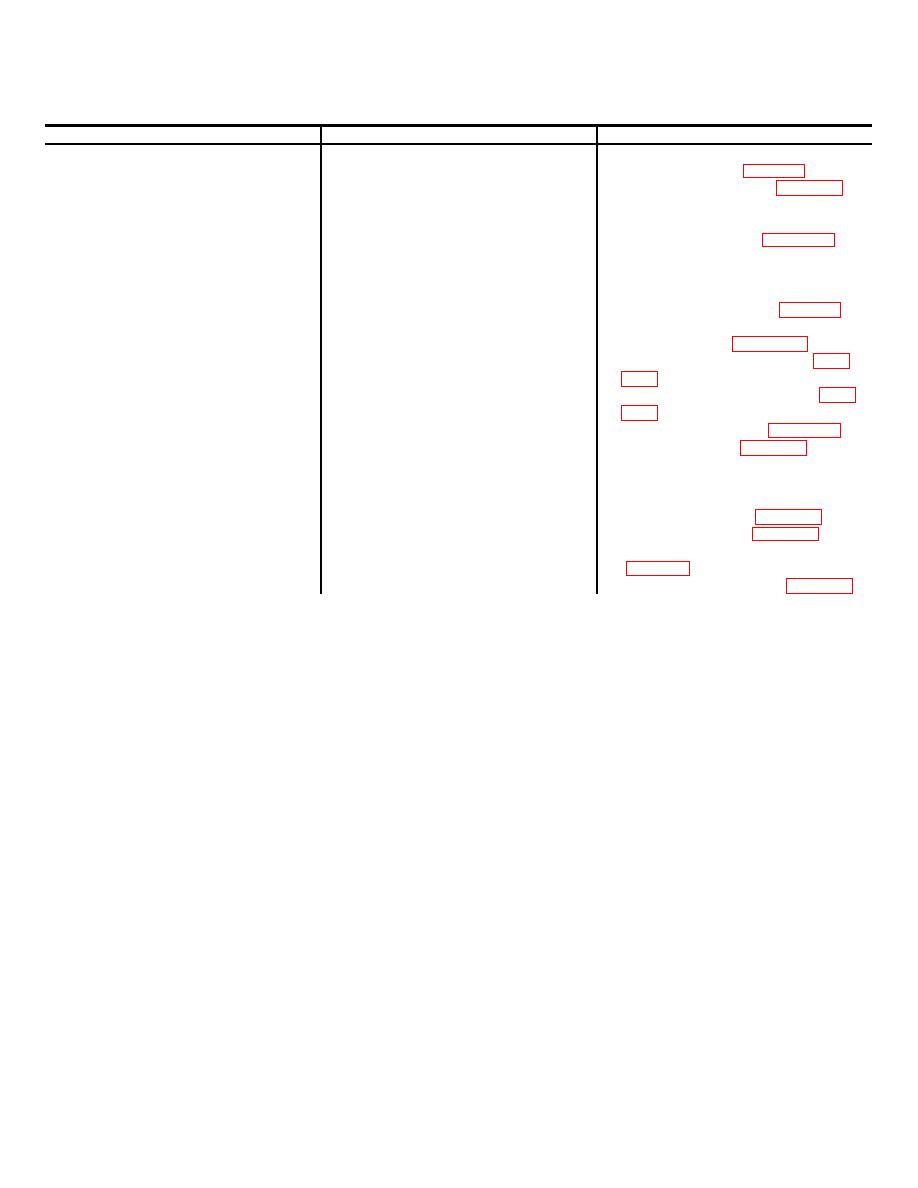

Table 2-1. Troubleshooting-Continued

Malfunction

Probable Cause

Corrective Action

6. Engine lacks power, smokes or

c. One or more valves stuck open.

c. Free stuck valves; Replace or

operates erratically,-Continued

regrind if burned (para 4-4).

d. Valve springs weak.

d. Replace valve springs (para 4-4).

e. Defective piston

e. Replace defective piston (para 4-

10).

f. Piston rings worn.

f. Replace piston rings (para 4-10).

g. Engine timing incorrect.

g. Correct engine timing (parp 4-12).

7. Engine makes excessive noise

a. Main or connecting rod bearing.

a. Replace defective bearing (para 4-

Defective.

10 and 4-11).

b. Flywheel rubbing on flywheel

b. Aline flywheel housing (para 4-9).

housing

c. Loose pistons pins

c. Replace pistons (para 4-10).

d. Excessive crankshaft end play

d. correct crankshaft bearings (para

e. Loose camshaft bearings.

e. Replace cramshaft bearings (para

f. Piston slap.

f. Replace worn pistons (para 4-10).

8. Pump runs with no fluid discharge

a. Impeller broken, worn, or

a. Replace impeller (para 5-4).

or with low discharge.

damaged.

b. Impeller-to-wear plate clearance

b. Add or remove shims as required

incorrect.

(par 5-4).

c. Wear plate excessively worn.

c. Replace wear plate (para 5-4).

d. Shaft seal defective.

d. Replace shaft seal (para 5-3).

9. Pump noisy.

a. Impeller or wear plate loose.

a. Tighten impeller or wear plate

b. Defective pump bearings.

b. Replace pump bearings (para 5-4).

SECTION III. GENERAL MAINTENANCE

2-5.

General

d. Protect disassembled parts from blowing

sand and dust which could later cause rapid wear of the

This section contains general maintenance procedures

gears, bearings, and machined surfaces.

which are the responsibility of direct support and general

2-7.

Care of Bearings

support maintenance personnel.

The paragraphs

a. Clean ball and roller bearings by placing

contained herein describe general practices applicable

to several assemblies or components of the centrifugal

them in a wire basket and immersing them into a

pump which would otherwise have to be repeated in

container of fresh cleaning solvent (FED. Spec. P-

each section of the manual assigned to those

D680). Agitate the bearings in the solvent to remove all

assemblies and components.

traces of old lubricant.

2-6.

Cleanliness

b. After the bearings are cleaned, dry them

a. Take care to assure that the workplace is

with clean, filtered compressed air. Take care to

clean before starting to disassemble the engine or pump

prevent spinning the bearings with the compressed air

parts.

jet.

b. Steam-clean the exterior of the engine or

c. Dip the cleaned bearings in clean engine

pump before starting disassembly to prevent the dirt

oil and immediately wrap them in lint-free paper to

from entering the bearings. Clean the exterior of engine

prevent the entry of dust and dirt.

2-8.

Seals and Gaskets

components with a cloth dampened with cleaning

solvent (FED. Spec. P-D-680).

Replace seals and gaskets of all components with each

c. If compressed air is used to clean the parts,

disassembly. The use of new gaskets and seals will

make sure the compressed air is free from dirt and

greatly reduce the possibility of leaking and will help

prevent the entry of dust and dirt after reassembly.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |