|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-258-34

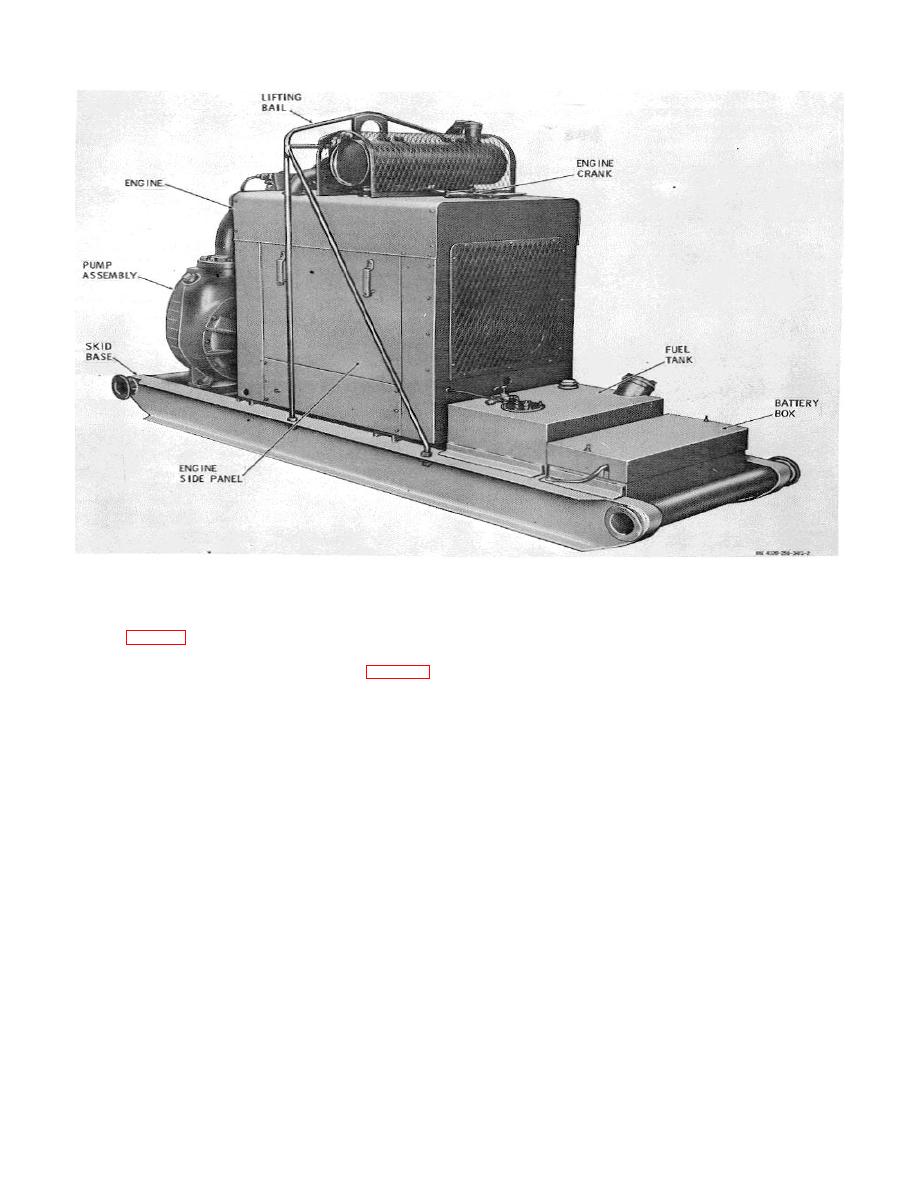

Figure 1-2. Centrifugal pump, right rear view.

b. The centrifugal pump has a 6-inch suction

engine when the engine speed reaches the preset

speed. The engine is enclosed in a housing that has

flange (7, fig. 5-1) secured to the front of the pump

coolant and oil drains ported to the outside of the

body and a 6-inch discharge elbow secured to the top of

housing for easy access. The engine uses an electrical

the pump body. The bearing housing (40, fig. 5-2)

starting motor, has magneto ignition, and uses an

joins the flywheel housing of the engine with the pump

alternator to maintain the charge of the battery which is

body, providing correct spacing and proper alinement of

depleted by operation of the starting motor. The

the parts. The bearing housing also provides the

conventional radiator-type cooling system uses a

bearing seats for the ball bearings that support the

pusher-type cooling fan which forces cooling air through

impeller shaft. The impeller is keyed to the end of the

the radiator from the inside out. It also maintains a flow

impeller shaft and is secured with nuts. The impeller is

of air around the engine to provide proper cooling.

enclosed in a close-fitting volute to provide efficient

pumping operation. A replaceable wear plate at the

front of the impeller takes most of the internal pump

This technical manual covers only the Barnes Model

wear.

US67CCG. No known changes exist in the equipment

c. The engine is a six-cylinder, water-cooled,

procured under this model number.

pressure-lubricated, four-stroke-cycle, L-head type.

Engine speed is governed by a flyball-type governor and

is protected by an overspeed governor that shuts off the

1-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |